BlueBee & Small Batch Manufacturing: Sculpteo Showcase

Posted By Zach Correa on Jul 9, 2014 | 0 comments

In 2008, a pair of engineering students had a habit of losing keys. After multiple lock changes, they decided to design something about it – a small device that can be attached to keys or left in a wallet that alerts you of its whereabouts. Now the device is available to everyone through BlueBee.

We’ve all been there: a night of merrymaking and a cab ride home only to be left at your doorstep in the rain wondering, “Shoot, did I leave my keys in the cab? At the restaurant?” Well now BlueBee has the answer.

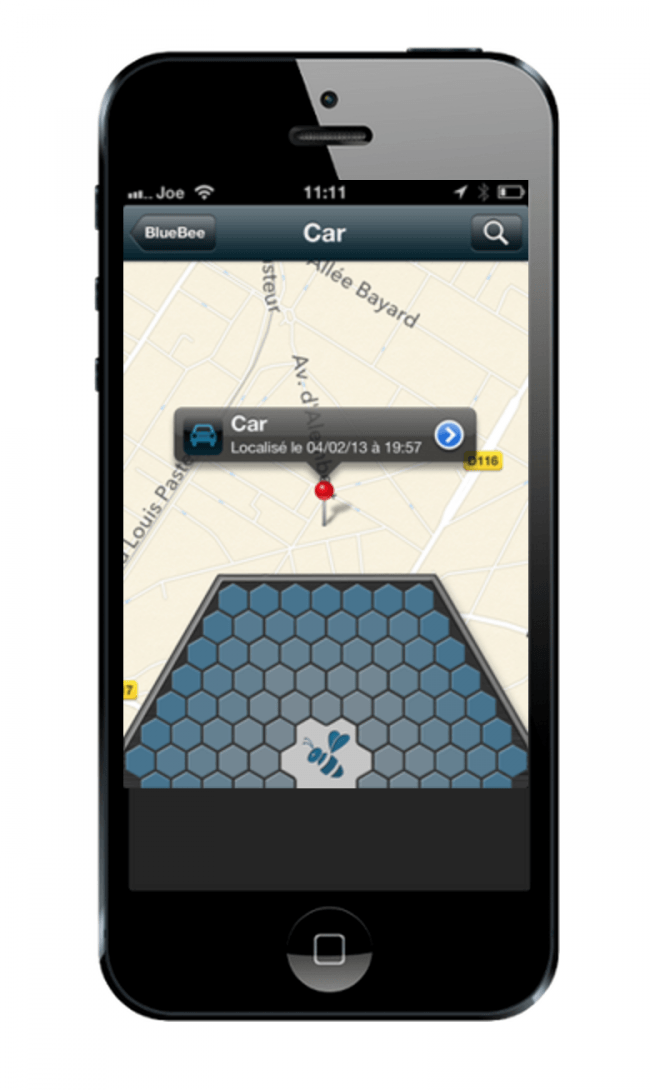

“BlueBee is a tiny electronic location device which communicates with an iOS or Andriod smartphone,” writes X6 Innovations/BlueBee co-founder Artem Rodionov. “With BlueBee, you will be able to locate your tagged valuables on a map and make them ring when you are close. Thus you will find out where you are parked or where your keys are . BlueBee also alerts you when your wallet is out of sight, so that you never forget it at a restaurant.”

BlueBee is a startup with infinite growth possibilities, as key-losing is a worldwide epidemic. But as they are still a small business, Rodionov writes of the advantages of 3D prototyping on a tighter scale.

“3D printing is an obvious solution for a start-up, especially if you follow the ‘lean start-up’ approach. It allows you to cut time and resources on prototyping, and thus to achieve a minimum viable product in no time.”

During the design and manufacturing process, Rodionov had many production options, including injection molding, though he warns against it, especially for small businesses:

“Instead of using 3D printing, we could have gone for a mold. In fact that’s what we did for our first product and this didn’t work out that well. Once you have ordered a mold, there is no way back and no room for changes. After producing and distributing a first series of the molded BlueBees, clients started telling us about all the little changes in product design which in their opinion would make it better. But there were nothing we could do about it but to wait for month until the second version of the product was fully ready.”

Rodionov finally explains one of the greatest benefits of 3D printing in small batches – the flexibility of the objects when it comes to a delivered product. When using 3D printing as the method of manufacturing, a design can continuously evolve.

“In our case 3D printing also turned to be a viable manufacturing method for a middle sized series production of the final product. Today, we deliver hundreds of 3D printed BlueBees to our customers. And every week we introduce small but meaningful changes into the product design. This allows us to continuously rise the quality of our product while experimenting new designs. Changing the color or the shape of the product is as simple as ever.”

If you’re interested in getting your hands on a BlueBee, be sure to check out their website. Or if you’re part of a small business, looking to get your object on the market, shoot our sales team a message!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook