Fendi Project : Sculpteo makes the difference

Posted By Allison Simonot on Jun 17, 2015 | 0 comments

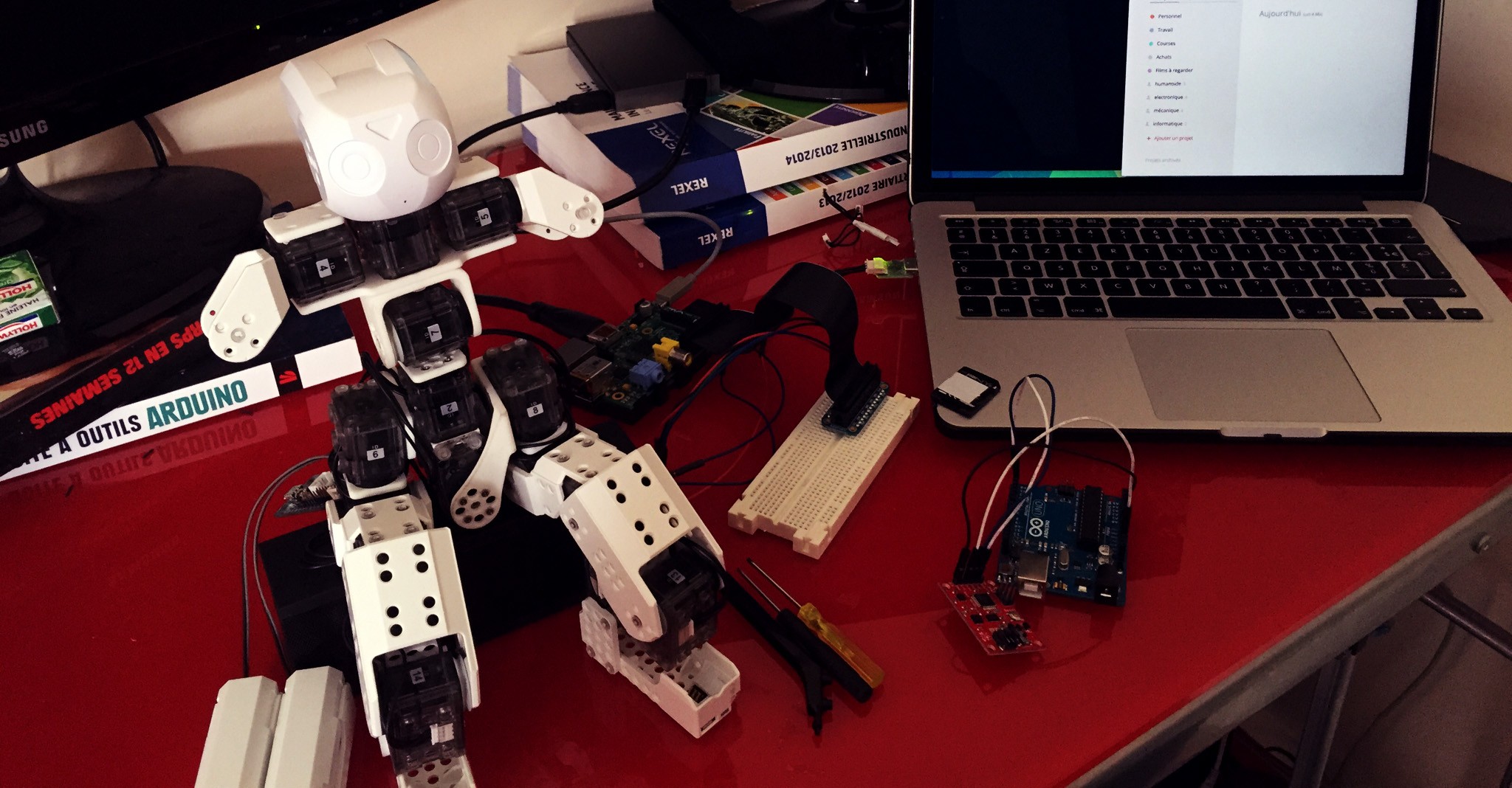

The Poppy project (the open-source robot that anybody can build) has made new followers ! In an article dedicated to the project, we explained that we 3D print the mechanical parts constituting the robot. It is now the turn of Alexandre Le Falher and Yusuf Gokol to embark on the Robotics adventure with their Fendi project. They run a blog where they share their enthusiasm in their robot project, and have not missed expressing a very positive and detailed opinion on our 3D printing service. It is quite natural that we wanted to also share their story.

What inspired the Fendi project?

The passion for humanoid Robotics and the desire to create a robot appropriate for the medical and educational fields. The purpose ? To make hospitalized children smile, and give young people the opportunity to learn CAD. Another goal in mind: build a team to compete in the Robocup! For this open-source project and open to participation, Sculpteo was chosen for 3D printing of the mechanical parts.

What’s Sculpteo’s 3D printing service most suitable for ?

Above all, affordability, an essential aspect for the team behind Fendi, which we don’t neglect at Sculpteo. Want to know how the cost of a piece is determined? It depends on many complex and interrelated factors. One of the factors is the quantity of material used to 3D Print the object. In this sense, a hollowed-out plastic part will always cost less than a full piece. Fortunately, among the optimization tools that we offer on our platform, there is the Hollowing tool. It allows you to scoop out your piece easily, while respecting the necessary minimum thickness for the material and the dimensions of your object. So you can save up to 60% of the cost of production of your piece!

Another economically advantageous tip we offer: economy production, a slower production method which adds a few days to production time, and you can save an extra 30% (an option available only for plastics for now). The Fendi team was able to make the most of it.

What features have been the most useful?

“Apart from the financial cost, Sculpteo has other technical and practical benefits that competitors do not offer.” Alexandre Le Falher

The team also highlights our unique advantages in terms of quality of service and ease of use of our 3D printing platform. The team especially appreciated our Multi-Upload tool, the ability to load multiple 3D models simultaneously. A function which “makes life easier” and prevents you from wasting time, especially when it comes to load all the mechanical parts of a future robot!

How does delivery fare?

No less than 8 parts were received on time and well packaged, yet surprising for the Fendi team they arrived in 4 deliveries (the team only paid for one). At Sculpteo, we ensure that you receive your different pieces as early as possible. This can result in the production of parts at multiple sites depending on the availability of machines. An additional cost for us, but a quality of service that we care about. Once the parts were received, the team only needed to assemble the robot. No problems with assembly, and of course : the team chose our plastic, an ideal material for the assembly of mechanical parts or prototyping.

Where is the project now? Fendi the robot already knows how to stand on one foot!

To follow the Fendi adventure, visit the project’s blog or the dedicated facebook and twitter pages.

You can also help the project by answering this 1 minute long survey (french only): tell the team which design you prefer for the head of the robot!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook