The Future of 3D Printing and Food

Posted By Arthur Cassaignau on Nov 11, 2015 | 0 comments

When talking about food and 3D printing, the expectations are quite high. Everybody’s thinking about a machine in the kitchen ready to create the most amazing meals by loading capsules of ingredients and just pressing a button. While we might not be that far from this vision (we’ve seen many projects in the past few years aiming at this), there is another face to this revolution that is more discreet. It’s happening in the food and food-processing industry rather than at home in our kitchens. 3D printing is a game changer for individuals, companies and startups that are bringing ways to automate processes and imagining the future of the way we consume food.

It’s a fact, machines will be more and more present in our kitchens. From small machines that can already boil water with vegetables and make soup to robots that behaves like a chef, the revolution is already happening. No need to wait for 3D printing. However, it’s becoming clear that 3D printing will also be part of this revolution. Many companies are presenting new offers to the market for both professionals and individuals (or even very exclusive uses – think of astronauts), while more established businesses have been using additive manufacturing to create prototypes, small series or even tools for the food industry for a long time now.

3D printed meals on demand and everywhere

It is no secret that saving every possible bit of time throughout the day is an achievement in itself, this is especially the case in the kitchen. However until now saving time in the kitchen has often meant eating low quality processed foods. Recent years (or even months) have brought us many solutions to find high quality food in our everyday life. Whether it’s a subscription service like Blue Apron or a delivery service like Deliveroo, we remain dependent on other people bringing the products that we will cook or even cooking it for us.

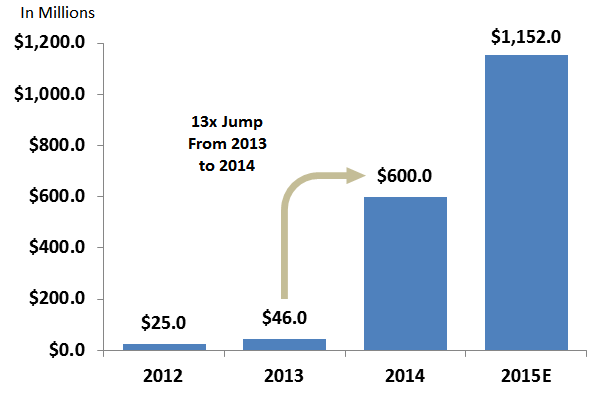

The trend is so huge that in July 2015, Techcrunch published a post called “The Billion Dollar Food Delivery Wars” which describes the whole ecosystem. From grocery delivery to meal deliveries, more than $1 billion was invested by VCs in 2014 in startups from this industry.

Martin Mignot, the author of this post, states that as an investor in Deliveroo, he sees three major trends:

- “Convenience always wins: on-demand will take-over the world”

- “Choice is key”

- “On-demand marketplaces have unfair advantages”

In a different post from May 2015, Techcrunch gave a few other figures that allows us to understand how big the food industry opportunities are. The author states:

“While just $46 million and $25 million were invested in food ordering companies in 2013 and 2012, respectively, a staggering $600 million was invested in 2014. And so far this year, we’ve had approximately $360 million invested to date, which when annualized, comes out to approximately $1.2 billion. That type of growth is not something you see often.”

Even more astonishing is the size of the market itself. The takeout and delivery market alone represents a roughly $70 billion market. Of that $70 billion, we consider that about $9 billion is happening online, which is about 13%. What if 3D printing was also a solution to disrupt the whole offline market?

Under this circumstances, it’s difficult to not see why food 3D printing becomes particularly attractive. It solves all-in-one many of the challenges that this emerging eco-system is facing. Thanks to recipes stored online and software that can operate machines with the highest precision, 3D printers will potentially have the capacity to create an almost infinite amount of meals on-demand, quickly and for a fair price (remember with 3D printing, you only use what you need and there is almost no waste).

As we now see marketplaces for restaurant deliveries emerges, marketplaces to fuel 3D printers with recipes will rise in the future. In this coming war to gain time in the kitchen, the biggest rivalry ten years from now might well be one between 3D printers and drones. Would you rather have a meal cooked a few blocks away and air-delivered? Or a 3D printer that does it right in front of you?

3D printing is preparing to enter this huge market. One of the first serious food related 3D printing projects was introduced on Kickstarter in 2014 by Natural Machines with its Foodini. The claim of the company was this:

Foodini helps create savory or sweet cuisine. The food is real food, made from fresh ingredients prepared before printing. Promoting cooking with fresh ingredients, Foodini manages the difficult and time-consuming parts of food preparation that often discourage people from creating homemade food.

Seen under the light, the statement of the company for their Foodini product is no different from the ones made by more “traditional” companies willing to disrupt the food delivery market.

The startup Bocusini is making the same claim by offering both a 3D printer for food (funded via Kickstarter) and a marketplace to pick recipes that the printer will be able to create. While recipes are still fairly simple, it’s easy to understand what they’re aiming for…on-demand and everywhere.

Understandably, Natural Machines and Bocusini are not the only companies eager to bring a ready-to-use product to the market. Since then, many initiatives have followed the same path. At CES 2014 in Las Vegas, 3D Systems for instance released a 3D printer called Chefjet Pro, that can utilize “a variety of confectionery recipes including sugar, fondant and sweet and sour candy in a variety of flavors”.

While taste is clearly not the strong suit of those printer (for now), the main upside is the possibility to literally bridge together design and food. Forms that are traditionally very difficult and time consuming to produce by hand are now a few clicks away.

In the main register, chocolate 3D printing has been on the rise since a few years.

In the on-demand and everywhere 3D printed food strategy, the winner clearly is NASA. The aerospatiale agency is planning on building food 3D printers to feed its astronauts. So is eating a pizza in space the future? Well, it appears so. NASA has indeed invested 125,000 dollars in a project to 3D print pizzas in space. The agency sees many upsides to this project. One of them is the ability to sustain very long term mission with a sufficient variety of food:

NASA’s Advanced Food Technology program is interested in developing methods that will provide food to meet safety, acceptability, variety, and nutritional stability requirements for long exploration missions, while using the least amount of spacecraft resources and crew time. The current food system wouldn’t meet the nutritional needs and five-year shelf life required for a mission to Mars or other long duration missions.

Feeding the planet thanks to 3D printing

At a global scale, the production of food itself comes with its number of challenges. Three of them are: the production of greenhouse gases, the overall growth of the population and the rising demand for more human treatment of the livestock.

The fact are here. On its website, the FAO (Food and Agriculture Organization of the United Nations) mentions that livestock is responsible for about 18% of global greenhouse gas emissions. Of course, animals themselves are not the only one producing greenhouse gas and CO2 emissions from the livestock sector are also directly tied to fossil fuel burning during production of fertilizer for feed production, the livestock production process, processing and transportation of refrigerated products. Tied with the growth of the worldwide population (which means the need of an even wider livestock), the question of greenhouse gas emissions within the food industry is far from being neutral.

Somehow related, the growth of food production is also as a big factor in the deterioration of the livestock treatment. More and more, societies are asking for better traceability of the animals and a more human treatment while they’re being processed into food.

As a solutions to those problems, companies, like Modern Meadows, are embracing a vision where it would be possible to grow protein artificially and deliver them through 3D printing.

The company was founded in 2011 with the vision to create artificial meat. After an incubation at Singularity University and some funding, it’s now aiming at being able to create protein and 3d print meat.

Sonina Chau from Horizons Venture, one of Modern Meadows’s investor, states :

“Both companies are trying to bring great food to the world’s table through technology that is much more environmentally friendly and effective in terms of ‘real cost’ to the world.”

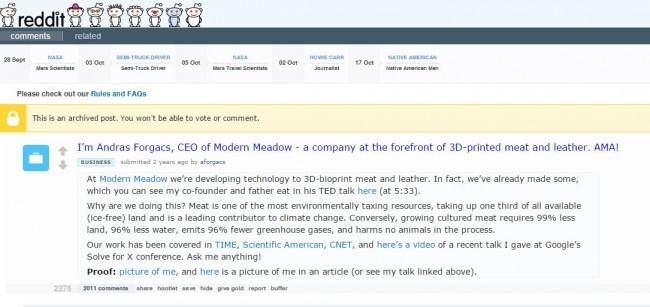

On his Reddit AmA (Ask me Anything, Andras Forgacs, is presenting himself as the CEO of Modern Meadow – a company at the forefront of 3D-printed meat and leather. The goal of the company is to reduce the footprint of meat (and other animal related products) to preserve the environment. Conversely, growing cultured meat requires 99% less land, 96% less water, emits 96% fewer greenhouse gases, and harms no animals in the process.

Since there is no hazard in life, Andras Forgacs is also a co-founder at Organovo (a publicly founded on the Nasdaq), a company which aim at doing the same job for the medical industry by growing human tissue to create organs.

If this solution won’t enter our everyday life tomorrow, it clearly is picking up on other trends of our current society like a growing interest for homegrown ingredients and home cooked food. Somehow, initiatives like Windowfarms are not that far away from 3D printing your own food.

Using 3D printing to innovate in the food and food-processing industry

The end consumer is not the only one showing an increased interest for 3D printing through new machines that will help him in his everyday life. There is another side to it. Companies of the food industry are also directly using 3D printing to innovative and bring new products to the market. Whether it’s to prototype or to integrate 3D printed parts into their finished products, we’ve seen quite a few examples of companies of the food industry at Sculpteo, that have used 3D printing. Rather than listing once again all the great uses of additive manufacturing, this section is dedicated to four industrial examples that we see every day at Sculpteo and that are for us key to understand what 3D printing is changing behind the scene of the food and food-processing industry.

Stating the obvious, the food industry is using food. And of course food means perishable goods. Fachaux, a company building industrial machines to separate fruits and vegetables by sizes, has been using 3D printing to overcome this issue and not waste to many food in the process of building the machines.

Fachaux came up with the idea to 3D print all forms and sizes of frutis and vegetables. Once 3D printed, fake batches of fruits or vegetables are used to create new machines and also to calibrate machines that have just been build.

Naturally, in the process of creating their different machines, Calfachaux is also using 3D printing to bring their prototype to life, before industrializing the parts through injection molding.

Procys is a company specialized in building machines to handle two industrial processes in the food-processing industry linked to biscuits and pastry making:

– The conveying of biscuits

– The process of stuffing donuts

Procys used 3D printing to prototype a reservoir that holds liquids. After several prototype, the company will use 3D printing to industrialize that specific part on one of their machines.

Blendbow is a machine that is able to create cocktails on its own. Morgan Fellous, the founder of the company, has had the idea 3 years ago when he had to wait a while before being served a cocktail. He told to himself that creating a machine that could automatized some generic cocktails would simplify the barman’s tasks.

In total, the project kept about 10 persons busy and 3D printing played a crucial part to develop the machine. It was used to create the prototypes and validates the mechanical parts. Using SLS 3D printing, the team behind Blendbow was able to achieve high quality and very precise parts to make the first units of the machine before industrialization.

So what’s next?

3D food printing does still face major obstacles. The technology remains expensive and complex. The level of complexity required to create good enough food is still far from being a viable alternatives to our very efficient ways (especially the new ones) of getting ready-to-eat food. As stated before, 3D food printers are not producing great tasting food yet. However, the first experiments are paving to way for a shift in our food consumption should it be here on earth or even in space.

Another area where 3D printing could make a difference concerns the production of the food itself, as companies like Modern Meadows are looking for new sustainable ways to grow food artificially. The fact is here, in 3 decades, the earth will be populated by almost 9 billion people for who we’ll have to find a way to produce and deliver food (among other things). 3D printing could very well be a way to solve part of the equation.

For now however, the real impact of 3D printing on the food and food-processing industry is more discreet and happen mostly when the food is being industrially processed. Company, ranging from startups to bigger companies, are more than never using 3D printing to innovate in the sector. If you’re among the ones that are also willing to push the food industry further with 3D printing, you can also check our dedicated page.

In the end, the future of eating might just look like this: “CTRL+P”

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook