Centre d'apprentissage 3D

Voir toutes les catégories

Connectez-vous

Si vous rencontrez une difficulté avec votre compte, contactez-nous

S'inscrire

Pour commencer l'impression 3D ou la découpe laser de vos pièces, vous devez créer un compte ici. Une fois cette étape passée, vous pourrez transférer vos fichiers et disposer de devis en temps réel.

Vous avez déjà un compte ? Connectez-vous

Home » Centre d’apprentissage » Les technologies d’impression 3D » Guide pour la Stéréolithographie: Qu’est-ce que l’impression 3D SLA?

Sculpteo propose un service d’impression SLA pour vous aider à fabriquer des pièces lisses et détaillées. Pour vous aider à comprendre tout le potentiel de cette technologie d’impression 3D, nous avons préparé ce guide complet de stéréolithographie.

Comment ça marche? Quel matériau d’impression 3D pourriez-vous utiliser pour fabriquer votre projet SLA ? Quels sont les avantages d’imprimer vos pièces en 3D avec SLA ? Suivez le guide.

La stéréolithographie (SLA) est l’une des plus anciennes techniques d’impression 3D jamais développées. Ce procédé de fabrication additive utilise un procédé photochimique pour imprimer en 3D un objet en résine.

La résine photopolymère liquide utilisée dans cette technologie d’impression 3D SLA est durcie dans une cuve. Le polymère liquide est exposé à la lumière lorsque la plaque de construction est déplacée, et le laser UV utilise cette exposition pour créer une coupe transversale. Il s’agit d’un processus couche par couche qui se répète jusqu’à ce qu’un modèle soit entièrement fabriqué. Retirer l’objet en construction de la résine (de bas en haut) fait de la place pour la résine liquide non durcie au fond du récipient, qui peut ensuite être utilisée pour construire la couche suivante de l’objet.

Le processus de photopolymérisation étant irréversible, il est impossible de ramener les composants SLA à leur état liquide. Ces composants SLA ne fondent pas lorsqu’ils sont chauffés ; au lieu de cela, ils vont brûler ! En effet, contrairement au dépôt de fil (FDM), qui utilise des thermoplastiques, les matériaux générés avec SLA sont formés de polymères thermodurcissables.

Parmi toutes les technologies d’impression 3D, la stéréolithographie (ou SLA) pourrait être l’une des techniques les plus anciennes jamais développées. Si l’on jette un coup d’œil rapide sur l‘histoire de l’impression 3D, le SLA apparaît comme le premier concept d’impression 3D. Dans les années 80, une équipe française d’ingénieurs, Olivier de Witte, Jean-Claude André et Alain Le Méhauté, s’est intéressée à la technologie de la stéréolithographie. Pourtant, malheureusement, ils ont abandonné leur projet et n’ont pas poursuivi leur demande de brevet en raison d’un manque de perspective commerciale.

Dans le même temps, Charles Hull s’est également intéressé à la technologie et a déposé le premier brevet de stéréolithographie (SLA) en 1986. Hull a breveté la stéréolithographie comme technique permettant de créer des objets 3D en ajoutant successivement de fines couches d’un objet à l’aide d’un support durcissable par ultraviolet.

Charles Hull est maintenant bien connu dans l’industrie de l’impression 3D car il a également créé 3D Systems Corporation, qui a lancé son premier produit, l’imprimante 3D SLA-1, en 1988.

1 – Préparez votre fichier 3D

La première étape pour démarrer votre processus de fabrication avec la fabrication additive consiste à créer un modèle numérique 3D du produit que vous souhaitez fabriquer physiquement. Vous pouvez le faire en utilisant un logiciel de modélisation 3D pour créer votre objet. Découvrez notre sélection de logiciels de CAO gratuits pour développer votre projet !

La préparation de votre fichier pour l’impression 3D avec SLA est une étape essentielle de votre processus. Ce fichier 3D doit être parfaitement imprimable. Chez Sculpteo, nous voyons beaucoup de modèles 3D avec des erreurs, résultant en des fichiers non imprimables. De plus, même si la pièce est imprimable en 3D, votre pièce doit être suffisamment résistante pour ne pas casser ou se déformer. Découvrez comment éviter ces erreurs courantes d’impression 3D. Bonne nouvelle pour vous, comme la technologie SLA peut créer un objet complexe, vous aurez la possibilité de créer un modèle 3D détaillé pour votre projet.

2- Préparez l’imprimante 3D SLA à imprimer

Les imprimantes 3D SLA sont généralement des imprimantes 3D de bureau à haute résolution. La majorité des paramètres d’impression sont définis par le fabricant et ne peuvent pas être modifiés. La hauteur de la couche et l’orientation des portions sont les seules entrées.

Si vous n’avez pas votre imprimante 3D SLA, vous pouvez utiliser un service d’impression 3D en ligne comme Sculpteo, et toute préparation technique sera faite pour vous par nos opérateurs ! Sculpteo utilise les imprimantes 3D Formlabs pour imprimer en 3D vos pièces, ces imprimantes sont à la fois qualitative pour produire vos pièces, et très fiables.

3- Processus d’impression 3D

Une fois toutes les vérifications de configuration effectuées, l’imprimante est prête à imprimer ; le laser durcira la résine photopolymère selon votre modèle 3D jusqu’à ce que l’impression soit terminée.

Il existe deux configurations différentes pour les imprimantes 3D de stéréolithographie : les imprimantes descendantes et ascendantes.

Les imprimantes descendantes placent la source laser au-dessus du réservoir et la pièce est construite vers le haut. La plate-forme de construction commence au sommet de la cuve de résine et se déplace vers le bas après chaque couche.

Les imprimantes ascendantes placent la source de lumière sous le réservoir de résine et la pièce est construite à l’envers. Le réservoir a un fond transparent avec un revêtement en silicone qui laisse passer la lumière du laser mais empêche la résine durcie de coller. Après chaque couche, la résine durcie est détachée du fond du réservoir lorsque la plate-forme de construction se déplace vers le haut.

4- Post-traitement

Après le processus d’impression 3D, les pièces doivent être rincées dans de l’alcool isopropylique pour éliminer la résine non polymérisée de leur surface. Certains matériaux doivent être durcis une fois que les sections lavées ont séché ; cette procédure aide les composants à atteindre une résistance et une stabilité maximales. Après avoir retiré les supports des pièces imprimées, vous pouvez ensuite poncer les marques de support restantes pour une finition propre.

Il existe différentes façons d’imprimer SLA ; comme nous venons de le voir, la principale différence est leur orientation. Il peut s’agir d’un processus ascendant ou descendant, selon l’imprimante 3D. En effet, les imprimantes 3D de bureau utilisent la technique bottom-up, comme les imprimantes 3D Formlabs, tandis que les top-down sont plus des imprimantes 3D industrielles. Les imprimantes SLA de bureau sont moins chères et plus faciles à utiliser. En revanche, les imprimantes 3D industrielles permettent la construction d’objets de grande taille grâce à leur volume de construction passionnant, mais elles nécessitent un technicien spécialisé pour être utilisées. De plus, ces machines 3D sont à grande vitesse.

Une autre caractéristique essentielle de l’impression 3D SLA est une structure de support pour imprimer votre pièce en résine. Encore une fois, ces supports sont plus faciles à développer pour les imprimantes 3D de bureau car ils s’apparentent aux supports de Fused Deposition Modeling (FDM).

Ceux-ci sont nécessaires pour imprimer correctement les surplombs et les ponts, par exemple. Vous pouvez choisir l’orientation de la pièce, en choisissant quelle exposition nécessite moins de supports. Pour les machines SLA industrielles, un support est toujours nécessaire. Tous ces supports doivent être retirés manuellement de la pièce imprimée en 3D.

De plus, le post-traitement fait également partie du processus de fabrication avec la stéréolithographie. À la fin du processus, la quantité est retirée de la plate-forme et l’excès de résine doit être retiré de la pièce. Ensuite, la pièce en résine subira un processus de durcissement dans un four UV, ce qui aidera la pièce finale à atteindre sa stabilité absolue.

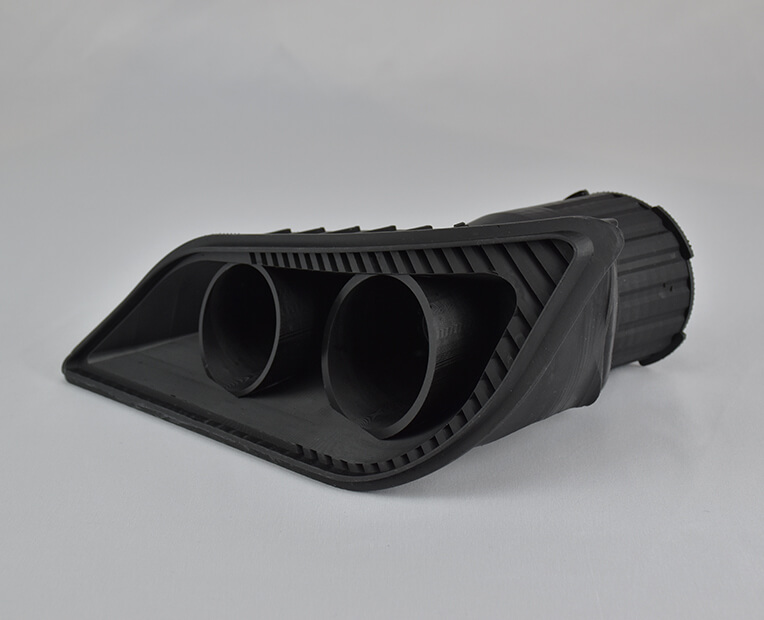

Choisir la stéréolithographie pour votre projet peut offrir divers avantages pour le prototypage ou la production. C’est une technique de fabrication rapide, permettant des pièces précises avec une grande surface lisse. Ces pièces en photopolymère n’ont pas la résistance du frittage sélectif par laser (SLS) ou des pièces imprimées en 3D FDM, mais peuvent généralement atteindre des niveaux de détail beaucoup plus élevés et des géométries très complexes.

L’impression 3D avec des technologies de résine peut offrir une étanchéité à l’eau, car les objets imprimés sont continus. Ceci est très utile si vous êtes confronté à des problèmes de débit d’air et de fluide.

Pourquoi les technologies de résine d’impression 3D telles que SLA peuvent-elles créer des pièces si précises ? La température est ici un facteur important. Des températures d’impression plus basses que les méthodes à base de thermoplastique qui font fondre la matière première se traduisent par une meilleure précision. Le processus d’impression en stéréolithographie se déroule à une température très proche de la température ambiante. Par conséquent, nous n’avons pas à faire face à la dilatation et à la contraction thermiques.

De plus, le réservoir de résine chauffé et l’espace de construction fermé fonctionnent ensemble pour créer des conditions presque similaires pour chaque impression !

Si vous recherchez une méthode d’impression 3D offrant un haut niveau de détail, alors SLA est la solution parfaite pour vos projets.

Une caractéristique des techniques d’impression 3D basées sur l’extrusion comme la modélisation par dépôt de fil fondu (FDM) est l’anisotropie, qui fait référence aux variations d’une couche à l’autre tout au long du processus d’impression. Pour des applications spécifiques, cette anisotropie limite l’utilisation de FDM ou nécessite des révisions supplémentaires de la géométrie des composants pour la compenser. Avec la stéréolithographie, c’est un peu différent. En effet, les imprimantes de stéréolithographie produisent de jolies pièces isotropes.

En combinant la chimie des matériaux avec le processus d’impression, il est possible de gérer étroitement une variété de paramètres qui contribuent à l’isotropie des composants !

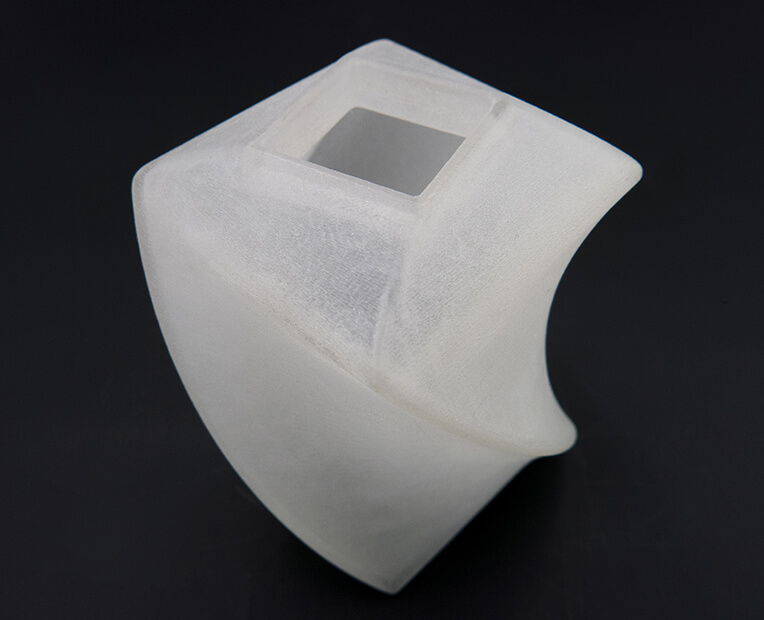

L’impression 3D en résine est également parfaite pour la fabrication de pièces décoratives ou de produits finis d’utilisation finale grâce à de grands détails et à des surfaces lisses. Vous pouvez facilement accéder à des finitions de surface semblables à des moules à injection en utilisant des technologies de résine. Contrairement à certaines autres techniques de fabrication additive (technologies de fusion sur lit de poudre ou filaments), vous ne pouvez pas voir les couches sur une pièce en résine ; la surface est parfaitement lisse.

La stéréolithographie présente de nombreux avantages mais n’est pas la technique de fabrication parfaite pour tout le monde. Voyons quelques exemples d’inconvénients.

Les composants SLA sont généralement fragiles et inadéquats pour certains projets techniques ou avancés. De plus, comme le photopolymère est sensible aux UV, ces produits sont susceptibles de se déformer et de changer de couleur lorsqu’ils sont exposés au soleil. Cela signifie que les qualités mécaniques et esthétiques des composants SLA peuvent se détériorer avec le temps.

Les structures de soutien peuvent également être gênantes. Ces supports sont toujours nécessaires et la section SLA doit être post-traitée pour éliminer les marques visibles laissées derrière.

La résine de prototypage SLA (stéréolithographie) est idéale pour produire rapidement des prototypes esthétiques. Le SLA est couramment utilisé pour générer des illustrations très détaillées et des prototypes non fonctionnels et peut être utilisé pour fabriquer des moules dans des applications de moulage de précision.

Le produit fini a une finition de surface lisse et mate. La résine SLA vous permet d’obtenir un aspect de produit fini pour votre prototype. Cette technologie d’impression 3D SLA est la mieux adaptée aux petites/moyennes pièces avec des détails élevés.

Grâce à sa précision, cette technologie peut être utilisée dans diverses industries telles que le médical, le dentaire, la conception de produits, le divertissement, la joaillerie, etc. !

Les matériaux SLA sont des résines liquides qui peuvent être sélectionnées pour l’application prévue de la pièce, comme la résistance à l’abrasion, la finition de surface lisse ou la résistance à la température. Par rapport aux imprimantes SLA de bureau, les systèmes industriels offrent une plus grande variété de matériaux, donnant au concepteur plus de contrôle sur les caractéristiques mécaniques de l’objet produit.

Sculpteo propose la résine de prototypage en SLA. Ce matériau d’impression 3D est idéal pour le prototypage rapide et peut améliorer l’ensemble de votre processus. Avec l’aide de cette résine, des pièces complexes et des prototypes inachevés peuvent être produits. Les produits créés avec des résines SLA et ce photopolymère peuvent changer de forme et de couleur lorsqu’ils sont exposés au soleil.

Peut-être que SLA n’est pas la technologie de résine parfaite pour vous. Découvrez quelques alternatives également disponibles chez Sculpteo.

La résine liquide est contenue dans une cuve ou un réservoir, durcie contre une plate-forme de construction, s’élevant lentement hors du réservoir au fur et à mesure que la pièce est formée, couche par couche. Ces deux technologies d’impression 3D sont similaires mais ont une différence principale : leur source de lumière.

Comme l’impression à jet d’encre, l’impression polyjet distribue des couches de photopolymère liquide durcissable dans un plateau de construction plutôt que des gouttes d’encre individuelles sur du papier.

Carbon est à l’origine de cette méthode d’impression 3D de résine. La production continue d’interface liquide, ou CLIP, améliore les inconvénients de la technologie d’impression 3D existante en donnant la priorité à un processus photochimique personnalisable par rapport à une stratégie mécanique conventionnelle.

Téléchargez votre fichier 3D, choisissez votre matériau et obtenez votre devis instantané !

Pour vos pièces en résine, Sculpteo propose les meilleurs services d’impression 3D en ligne. Les pièces commandées en résine Prototypage peuvent bénéficier d’un mode « express ». Les commandes passées avant 15h30 (GMT + 1) seront prêtes à être récupérées ou expédiées avant 11h00 (GMT + 1) le lendemain dans notre usine. Une option parfaite si vous êtes pressé et avez besoin de valider un projet le plus rapidement possible.

Contactez nos experts en impression 3D si vous avez des questions sur la stéréolithographie et toutes les applications possibles.

Recevez les dernières actualités de l’impression 3D

Inscrivez-vous à notre newsletter pour tout connaître des dernières technologies d’impression 3D et de leurs applications, mais aussi des nouveaux matériaux et logiciels 3D.

Connexion avec Google

Connexion avec Google Connexion avec Facebook

Connexion avec Facebook