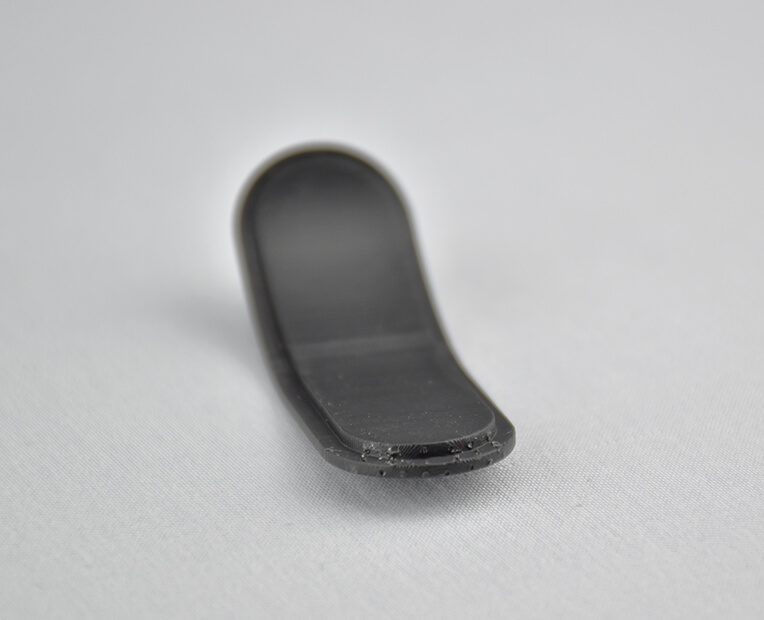

Layer thickness : 100µm

Accuracy : ± 100µm (Over 90% of scanned data within +/- µm)*

* Data provided by Photocentric

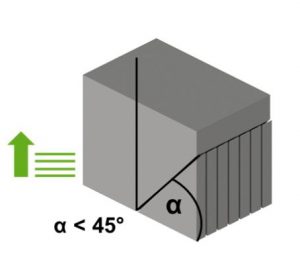

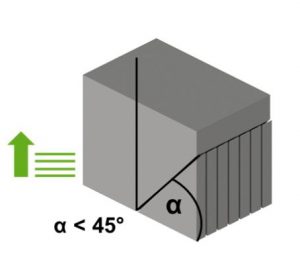

Angles under 45° require support structures.

Please keep in mind that surfaces that have connection with support won´t be as smooth as the surfaces without support.

Additional supports structure might be needed to prevent deformation during printing and post-processing.

Support structures on edges, holes and corners are difficult to remove and sometimes not possible.

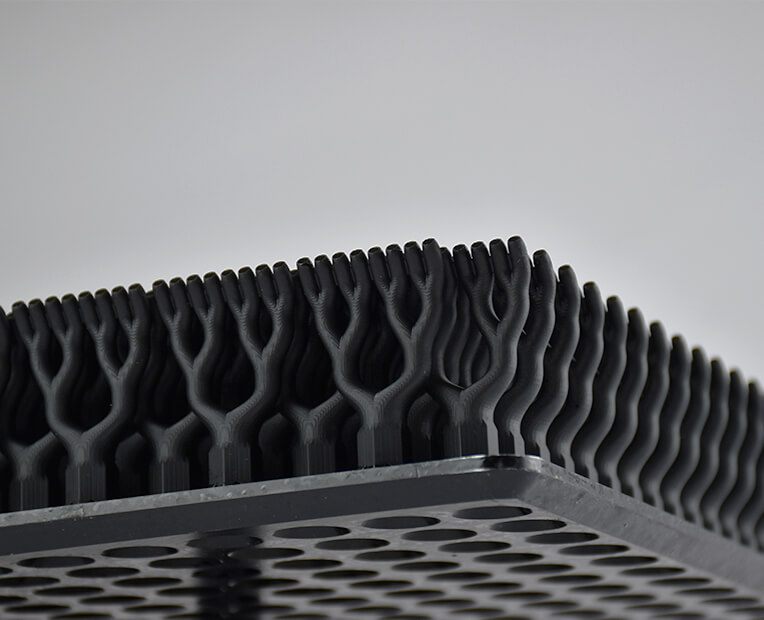

Minimum height and width details | Embossed : 0.3 mm

Engraved : 0.3 mm

|

| Ratio Depth / width | 1/1 |

A detail’s minimum precision is mainly determined by the resolution of our 3D printers. However, during the cleaning process, a fine layer of detail can also be lost. In order for a detail and text to be visible we recommend following our recommended sizes at the very least.It’s possible that particularly fine embossings and engravings will not be visible, as the carving could get filled with excess powder that is later unable to be cleaned out. If an embossing or engraving is an essential part of your design we recommend making them as deep as possible. To ensure a better powder removal (thus a better detail visibility), the width of your details must be at least as big as depth.

It is not possible to print a 3D file containing several objects, that’s why we cannot accept files that contain clusters of multiple objects. However, don’t worry, this doesn’t mean you’ll pay more for your multiple objects: to reduce the 3D printing cost, we set up a different price calculation as soon as you order two or more objects with this technology.

You can also use our online tools and see our tricks and tips on how to reduce your 3D printing price.

To get more information on our additive manufacturing service, you can contact our qualified sales team.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook