On-demand manufacturing service

- ISO 9001

- Fast Turnaround

- Secure File Upload

Boost your production with a game-changing manufacturing process

Boost your production with a game-changing manufacturing process

Using additive manufacturing and adapting your production to demand will be the wisest choice to make. With additive manufacturing you avoid this minimum order quantity, which can be particularly useful to produce limited editions or if you just need a few spare parts. No more busy warehouse: all you need are 3D files. You get the opportunity to use Just in Time Manufacturing and become as reactive as possible to the market demand.

Order your 3D printed parts in just a few clicks!

Upload 3D file

Review Printability

Instant Quote

Receive Your Parts

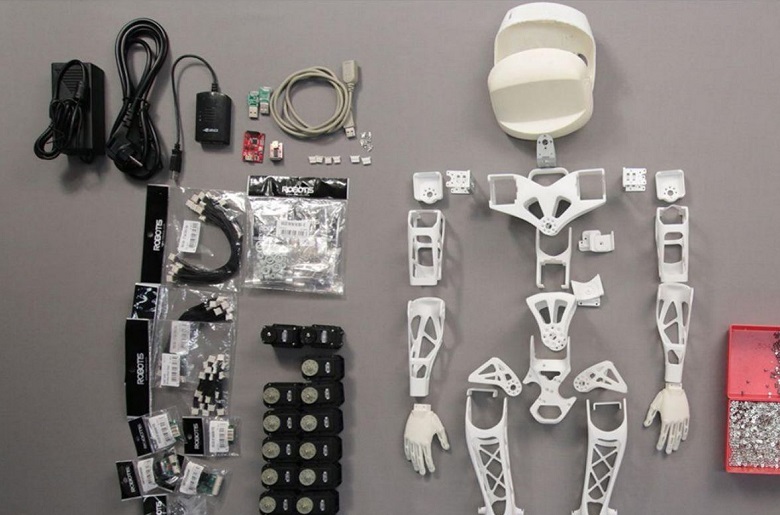

CUSTOMER STORY

Hexadrone is a french company specializing in the development of mechatronic systems for civilian and military UAVs. Hexadrone also offers more than 3000 products, OEM parts, and RTF drones via their online platform. From prototyping to on-demand manufacturing, high-quality, customizable drones, Hexadrone found its success with Sculpteo’s online 3D printing services.

On-Demand Manufacturing with 3D Printing

From Prototyping to Production with 3D Printing

Innovation and Rapid Prototyping with 3D Printing

Innovation and Adaptability with 3D Printing

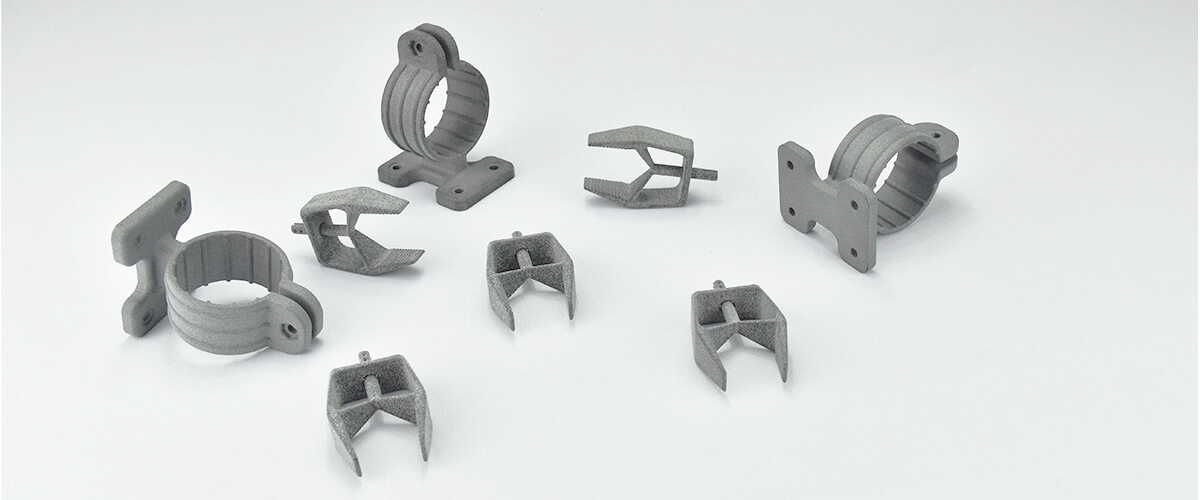

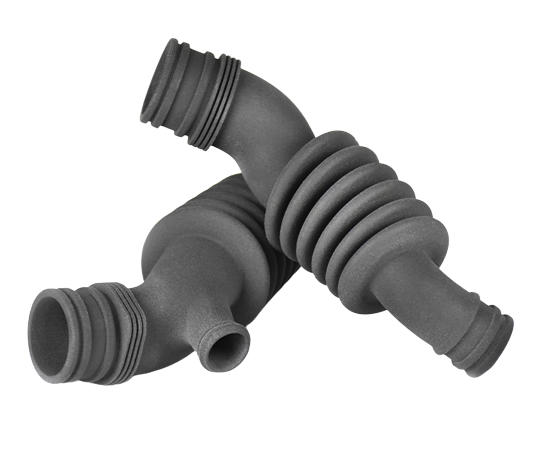

Choose materials adapted to your projects

Sculpteo offers a large catalog of 3D printing materials, adapted to all your projects and to the production of your series and limited editions. Feel free to scale your production using high-performance and accessible materials.

On-demand manufacturing, a real game-changer for your business!

On-demand manufacturing is making it easier for small businesses to compete with larger ones. By using on-demand manufacturing, small businesses can offer custom products and faster lead times, which can help them stand out in a crowded marketplace.

This manufacturing technique is also allowing businesses to be more agile and responsive to changing customer demands. With the ability to quickly produce new products or variations of existing ones, businesses can adapt to changing market conditions and stay ahead of the competition.

Finally, on-demand manufacturing is helping to create a more sustainable manufacturing industry. By reducing waste and excess inventory, businesses can minimize their environmental impact and operate in a more responsible way!

What are the reasons to use 3D printing on-demand manufacturing

Additive manufacturing is a way to simplify your processes with on-demand manufacturing to get the parts or series you need when and where you need them! Benefit from:

- Reduce costs

One of the most significant benefits is the ability to reduce inventory costs. With traditional manufacturing, businesses must produce a large number of products in advance and store them in a warehouse until they are sold. This can tie up a significant amount of capital and can also result in excess inventory that may never sell.

- Faster lead times

Since products are only produced in response to customer orders, there is no need to wait for inventory to be restocked or for products to be manufactured. This can lead to faster delivery times and a more responsive supply chain.

- Efficiency

On-demand manufacturing can also lead to more efficient use of resources. Since products are only made when there is demand, there is less waste and less need for excess inventory. This can result in lower costs and a more sustainable business model

Try out on-demand manufacturing today with Sculpteo

Using an online service bureau such as Sculpteo, there is no minimum order quantity, from a single object to 10 000+ parts, you can 3D print the exact amount of parts you need. This is why additive manufacturing is particularly adapted to the creation of limited editions.

With +10 years of expertise in additive manufacturing for production and prototyping, Sculpteo is also offering rigorous quality control. With our online 3D printing service, you get professional 3D printing is at your fingertips. Create a free account and upload your 3D files, select your material, technology, and post-processing options, and order online.

We’ll take care of the rest in our industrial ISO 9001 factory.

End Overproduction with On-Demand Manufacturing

It might be time to rethink your supply chain in order to optimize your business production and finances. On-demand manufacturing adds flexibility to your business to face unpredictable demands or events. This is a way for you to focus your resources on only fulfilling what you are going to be paid for, rather than wasting energy, time, and money on building stock. Moreover, being flexible enough in your manufacturing process allows you to adapt to the variability of demand. On-demand manufacturing is changing the manufacturing industry, be a part of it and get the reactivity to compete!

Are you ready to boost your company by using additive manufacturing for your on-demand production? Learn more about the benefits of this 3D printing manufacturing technique.

Why is Supply-Chain Resilience so Important?

What is supply-chain resilience so important and what are the advantages for your business?

The Scalable Manufacturing Playbook

Get the Guide to make your business more scalable with 3D printing.

How is 3D printing creating new business models?

Follow the guide and get ready to be inspired by these business model ideas. What is changing exactly in your business strategy while choosing to implement additive manufacturing?

What is traditional vs on-demand manufacturing?

Traditional manufacturing typically involves producing goods in bulk quantities through a set production process. The process usually involves the creation of a physical prototype, followed by mass production in a factory. This type of manufacturing is often associated with economies of scale, where the more products are produced, the lower the cost per unit. Traditional manufacturing also involves long lead times, as the production process requires significant planning and set-up time.

On-demand manufacturing, on the other hand, is a more flexible and responsive manufacturing approach that produces goods only as they are needed. This approach allowed manufacturers to respond quickly to changing market demands and produce customized products in small quantities. On-demand manufacturing typically involves the use of digital manufacturing such as 3D printing. This type of manufacturing is often associated with faster lead times, lower inventory costs and more sustainable production methods.

What is an example of on-demand manufacturing?

3D printing is an example of on-demand manufacturing. With no minimum order, it is possible to print the exact amount of parts you need when you need them.

You will have access to a wide range of technologies and 3D printing materials.

What is on-demand manufacturing?

On-demand manufacturing is the creation of products in response to the market’s demand when companies usually manufacture large quantities and stock them to sell them later.

This approach of on-demand manufacturing is more agile, responsive and efficient, becoming a game-changer for businesses of all sizes.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook