| Standard layer thickness | 100 – 120µm |

| High Definition layer thickness | 60µm |

| Accuracy | ± 0.3% (minimum of ± 0.3 mm) |

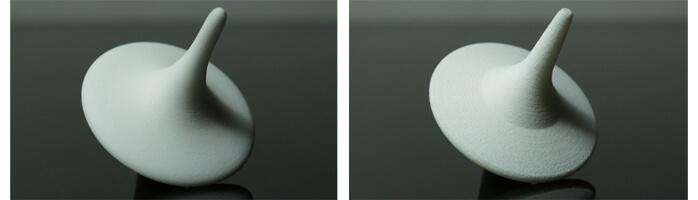

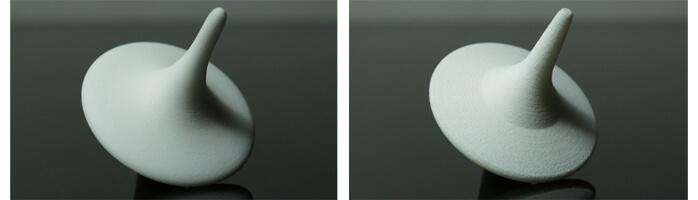

The picture shows on the left hand side an object printed in resolution 60 µm, and on right hand side resolution of 100- 120 µm

Sculpteo has two layer definitions available. A standard definition of between 100 – 120 µm and a high definition of 60 µm.

| Minimum wall thickness (flexible) | 0.8mm

|

| Minimum wall thickness(rigid) | 2mm

|

| Minimum wall thickness stemmed elements | 0.8mm with support

1mm without support

|

| Minimum wall thickness particular design aspects | 1-2mm |

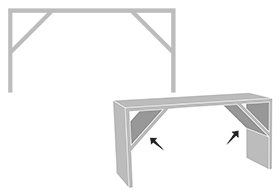

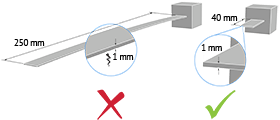

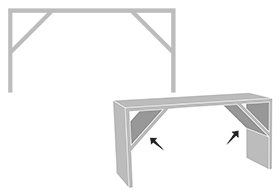

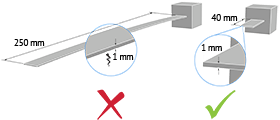

The walls of your design must adhere to a minimum thickness of 0.8 mm in order to guarantee the structure will not break. If the walls of your model are less than 0.8 mm, you can add a support structure to maintain stability.

A stemmed element is a design aspect which is at least twice as long as it is thick. For unsupported and stemmed elements or parts of the design with a particular design constraint, it is also important to respect a minimum thickness of 1 mm in order to guarantee the object will not break.

Tip

Add a support structure to maintain stability. For example, if you are modelling a bust of a person, you can attach thin aspects of the design like the ears in more places around the model’s head. Doing that will avoid cantilevered and easily breakable elements in the final print.

With a 0.8 wall thickness, your design will be slightly flexible. To obtain more rigidity, we advise a 2mm wall thickness.

Good to know

Thin walls supporting large, heavy Nylon PA11/12 (plastic) models can warp under the weight of itself.

Sculpteo offers an online solidity check tool which highlights parts of the print that may be too thin for a print. From there you are able to tweak your design in order to create an object that is an appropriate thickness. To use it, you just need to upload your 3D file, select your material and click on “Verification” tab.

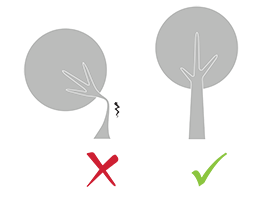

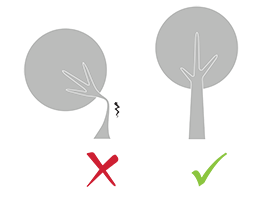

It is also important to keep in mind that the object is to be printed into real life. Thus if a thin aspect is supporting something that is too heavy for it, it may break – even though it is possible within the physics provided by your 3D modeling software. We recommend adding a bit of thickness to the places that will get a lot of handling, or that support the most weight.

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

| Minimum size of details | 0.3 mm |

| Minimum height and width details | Embossed : 0.4 mm

Engraved : 0.5 mm

|

| Minimum height and width for a readable text | 0.5mm |

| Enlargement ratio | 1/1

|

A detail’s minimum precision is mainly determined by the resolution of our 3D printers. However, during the cleaning process, a fine layer of detail can also be lost. In order for a detail and text to be visible we recommend following our recommended sizes at the very least.

It’s possible that particularly fine embossings and engravings will not be visible, as the carving could get filled with excess powder that is later unable to be cleaned out. If an embossing or engraving is an essential part of your design we recommend making them as deep as possible.

| Enclosed parts ? | Yes |

| Interlocking parts ? | Yes |

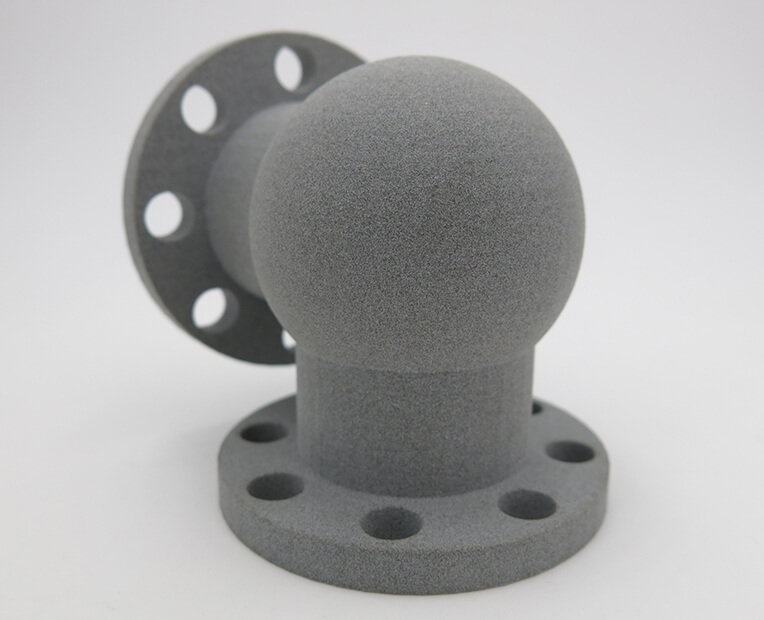

Our Nylon PA12 (plastic) material has the ability to print the most complex designs of our materials thanks to Selective Laser Sintering technology. An example of a complex design is a volume enclosed within another volume, like a chain or maraca. Our printers have the ability to print a fully interlocked chain, with no support structures to remove.

| Minimum spacing between fixed walls | 0.5 mm |

| Minimum clearance between parts | 0.5 mm |

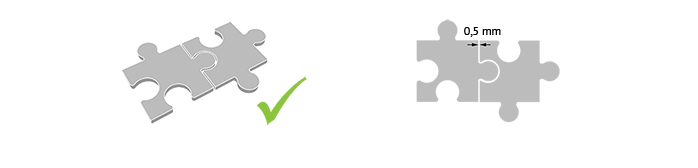

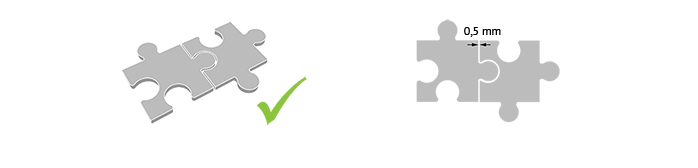

For a successful 3D print a minimum clearance between objects is required to allow excess material to be sand blown out. If this space is not left within the design, the object will be a solid. This is particularly important for articulated objects – as the space left between the walls will define the object’s ability to move.

Do not forget

Clearance should be at least 0.5 mm, however that is the minimum for small objects. Larger objects require more space between their parts. This is due to the SLS printing process. Our printer beds are heated during the process, and larger objects are heated for longer periods. A small space between large objects runs the risk of melting together as it remains under heat for a long period of time. In some other cases, holes should be added to allow us to drain for the excess powder material within the clearance.

| Assembly ? | Yes |

| Minimum space | 0.5 mm |

Objects printed in polyamide can be printed to be assembled. As long as a width of at least 0.5 mm is left between the different parts of the object.

Our online hollowing optimization tool has the ability to greatly reduce the price of a print by reducing the amount of material used.

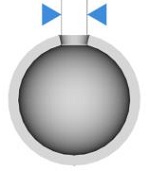

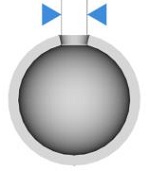

Using the tool requires adding two holes to your model, which will serve as the drain for the excess powder material within the object. The minimum size of these holes is determined by our website. Otherwise it is possible to hollow your object manually in your 3D modeling software.

| Files with Multiple Objects ? | No |

It is not possible to 3D print a 3D file containing several objects with our 3D plastic printers.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook