Design for Additive Manufacturing: Everything you need to know

What is design for additive manufacturing (DfAM), and what are the benefits? We are going to see how this design could be a real asset for your business.

Login

If you have any trouble logging in to your account, contact us.

Sign Up

To start 3D printing or Laser Cutting, you'll need to create an account here. Once done, you'll be able to upload your files and get live quotes of yours parts

Already have an account? Log In

3D Printing is the shortest path between your ideas and a functional prototype in your hands. 3D printing can be a strong ally at the early stages of your product development.

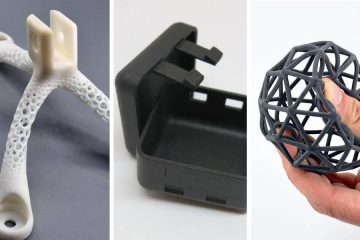

Prototype and iterate with Stereolithography (SLA), Selective Laser Sintering (SLS), or Fused Deposition Modeling (FDM) technologies.

Koovea is a startup based in Montpellier, south of France, specializing in connected temperature monitoring for the logistics of temperature-sensitive products. Their challenges? Develop rapidly a sensor resistant to extreme temperatures and respond to their client’s needs faster by offering customized versions of their products.

Benefit from an extensive catalog of 3D printing technologies, from Stereolithography to Selective Laser Sintering and HP Multi Jet Fusion. Using our online 3D printing service, you will access cost-effective and accurate 3D printing materials to give life to your proofs of concept and functional prototypes. Powder-based or resin options are available for your RP process.

Rapid prototyping with 3D printing will help you bring your project to the next level in no time, bringing your ideas to reality efficiently and reliably. Benefit from the rapid prototyping tools offered by additive manufacturing:

Prototypes are an essential step in your product development. Before a more costly step of production, you need to evaluate the design and functionality of your product. An excellent rapid prototyping technique is just what you need! Rapid prototyping allows engineers and designers to manufacture and test their products faster and iterate as much as necessary. Whether to create a scale model of a physical part to validate the shape or its visual aspect, try out an assembly, or build functional features and test them, rapid prototyping will help you achieve your goals in time. Some game-changing technologies, such as additive manufacturing, allows you to create your high-fidelity prototypes,

concept models and functional prototypes with an excellent surface finish. Additive manufacturing technology can become your true ally, for all kinds of applications with advanced technologies such as SLS, MJF, Binder Jetting, Polyjet and other technologies. Get rid of the disadvantages of manufacturing technologies such as CNC machining and benefit from the flexibility you deserve to grow your projects.

Additive manufacturing can boost your company, not only thanks to rapid prototyping. Discover how you could benefit from a more scalable, flexible, and resilient manufacturing process for prototyping and production.

What is design for additive manufacturing (DfAM), and what are the benefits? We are going to see how this design could be a real asset for your business.

3D printing prototypes: what are the advantages? Discover how 3D printing can help you develop advanced prototypes thanks to a large variety of materials.

How to identify 3D printing opportunities for your business? Find out our 10 best tips and see how 3D printing could be a great asset for your business!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook