3D print a perfect part: the ultimate guide to 3D printing Lightweight Structures

Posted By Kat Plewa on Sep 19, 2018 | 0 comments

To produce the ideal product there are lots of factors to consider. One of the most important ones is lightweight. 3D printing can bring you just the answer you are looking for. Additive Manufacturing can provide you with materials matching just your production needs or it can also help you to redesign your parts in a more efficient and innovative way. With our blog post, you will learn about the benefits of implementing lightweight structures in your objects as well as the best ways of achieving lightweight structures. Follow the guide!

10 benefits of implementing Lightweight Structures in 3D printing

The biggest myth about 3D printing technologies is high production costs. Indeed, Additive Manufacturing is a young technology, but it’s not necessarily a disadvantage. Looking at that fact from a different perspective, we see how much potential 3D printing has! We can approach it with an innovative and fresh take on production methods and shape it accordingly to our needs.

Discover new design freedom with lightweight structures

First of all, 3D printing allows for a totally new level of freedom when it comes to structures designed just for your needs. With Additive Manufacturing you can reach and adjust the parts in ways that before were unreachable, for instance, inside of your parts. That leads to material usage reduction, which obviously affects in lightweight products and lower production costs.

Shape your product accordingly to your needs

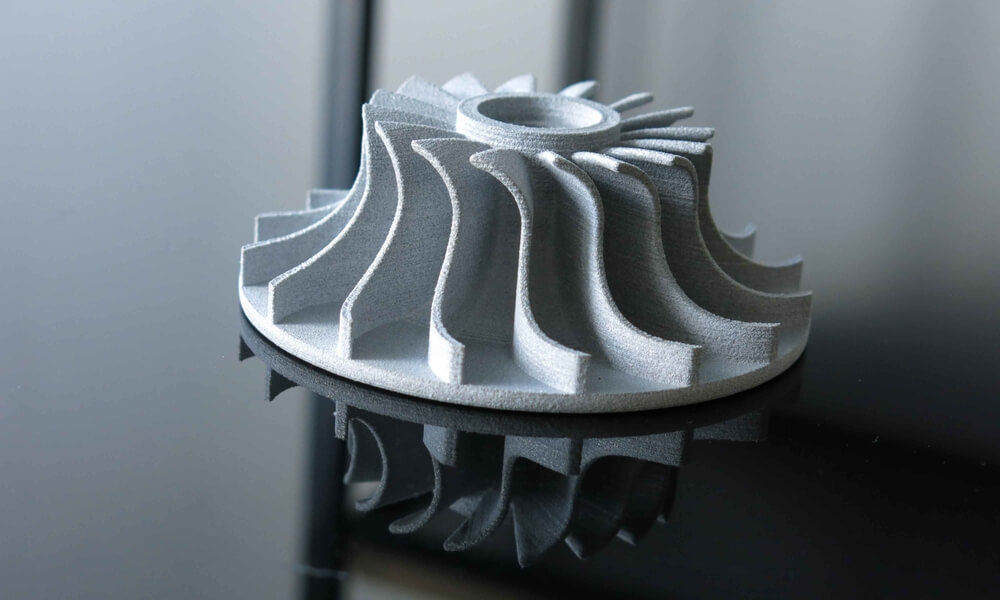

Thanks to 3D printing you can also design and then produce your parts to exactly fit your manufacturing restrictions. Additive Manufacturing is a revolution in that matter as it’s driven by your production requirements rather than by the technology’s limitations. It allows for a high level of complexity, allowing you to implement any essential mechanical components and structures designed for your parts to be fully functional. That also opens the door to development of absolutely new, advanced solutions for materials and manufacturing issues.

Create your own manufacturing materials

Last but not least, Additive Manufacturing technologies can adjust not only the shape and complexity of your parts. They also provide you with still undiscovered opportunities to design using exactly the materials you need for your production! How amazing is that? You can already choose from different types of materials, from elastic plastics, heat resistant 3D printing materials to very strong metals. But that’s not all, the 3D printing industry keeps surprising us with ground-breaking news all the time, such as 3D printed skin or heart. Now, if we can 3D print skin tissue, imagine what a huge change Additive Manufacturing can bring to your production!

How to make the most of 3D printing when it comes to the design process?

Additive Manufacturing offers lots of ways to improve your production with lightweight structures. You can find inspiration in nature to fill your parts with lattice structures, making your object lightweight, but strong. Or you can hollow your parts with us, it’s as easy as uploading your 3D model to our website. And if that’s not enough 3D printing also gives you the freedom of developing your own lightweight materials! Let’s have a closer look at all the prospects of empowering your manufacturing process with 3D printing Lightweight Structures.

Hollow your weight out

One of the most well-known design features of 3D printing is hollowing. As mentioned above, with Additive Manufacturing methods you can reach and edit your parts in places that are unreachable with traditional manufacturing methods. With 3D technologies, you can literally see through your parts and adjust them accordingly. With that new ability, you can also hollow the objects to achieve material reduction and therefore lower your production costs.

It might sound complicated, but with Sculpteo you can easily hollow your parts while placing your order! As simple as that, all you have to do is to upload your 3D model to our website and choose the hollowing option. Find the step-by-step guide here. And, if you will still feel uncertain, don’t hesitate to contact us, we’re always here to help!

Don’t waste money: implement Lattice Structures

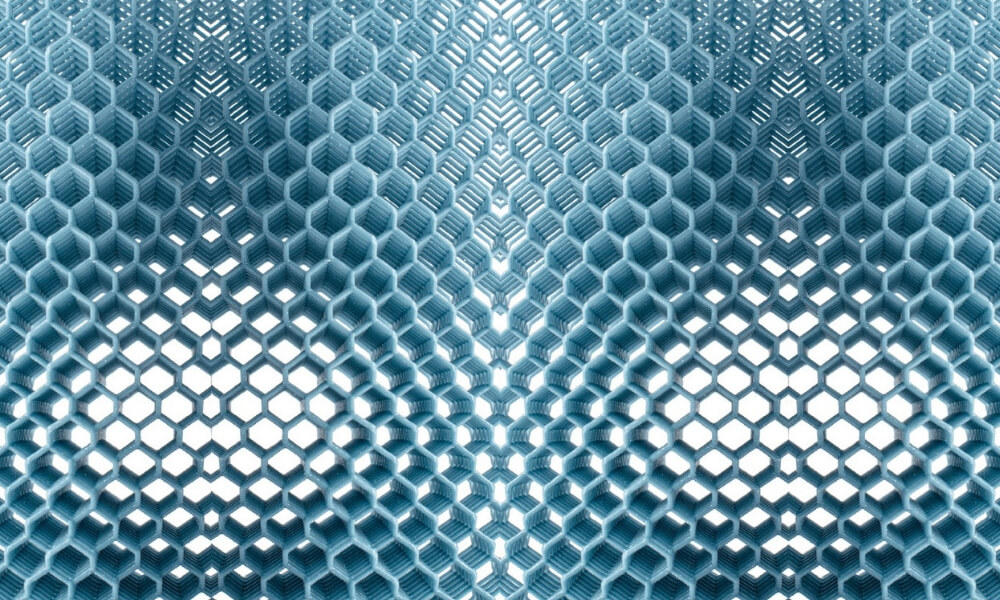

Hollowing your parts can be very beneficial for your production, but it’s not always the best from the design point of you. If your parts need to withstand big amounts of weight and stress we suggest for you to fill them with Lattice structures. Lattice will help you to keep the strength of your parts, but keep them lightweight.

There are several patterns of lattice called infill, for instance, a honeycomb, triangular or a grid. This design of lightweight structures will be highly beneficial for your production. You can adjust the lattice’s thickness, the percentage of infill and the pattern to match exactly for your production needs. And don’t worry, you don’t have to design those patterns yourself! There are plenty of lattice generation tools. Moreover, lightweight structures can be hidden inside of your object, or if your 3D printed model won’t be visible anyway, they can also substitute the whole construction and walls of your parts.

Choose the right material, or design your own

Another, crucial aspect of your parts to be lightweight is the material you choose to manufacture them with. 3D printing offers a wide range of materials with different characteristics, from elastic plastics to heat-resistant metals. Some materials will be more expensive than others, but you have to take in consideration different values and prioritize the features your object should have, very often that’s lightweight, and the restrictions it has to meet.

As Sculpteo we want to provide you with the best 3D printing experience. You can choose from our materials the perfect one that will be ideal for your production. Learn about material properties and pick the ideal one for your product. For example, if your parts need to be flexible, we have several options, such as PEBA for SLS technology. Or maybe your parts have to be lightweight but at the same time have a high level of resistance to heat?

Our 3D printing heat-resistant plastic: Alumide

Yet another important fact about 3D printing is that it gives you the possibility to develop new material properties just for your needs. 3D printing keeps surprising us with the usage of lightweight materials. Indeed, we already discover the strongest material humans ever produced, Graphene for Additive Manufacturing. Or a foam ink which is very robust, but also lightweight and stands out for shape memory- the ability to coming back to its shape after it’s under stress. And have you heard about conductive 3D printing material properties? The possibilities are just endless! So, if the material you need doesn’t exist yet, maybe it’s time to discover it?

Get inspired with nature

Nature can influence your product development in many ways, from the development of new materials to the design of your parts. How does grass come back to its shape after we step on it? It’s lightweight and seems fragile, but grass is actually very strong and can survive different weather conditions as well! Nature came up with many lightweight, but robust designs, which we can use to our benefit and construct our parts.

Sometimes the most simple answer is the right one. And that’s exactly how nature works. It doesn’t overcomplicate things, it creates perfect solutions for its needs. As humans, we have a great ability to observe and learn. Whether looking for new ways to construct parts or studying new materials, we first have a look at how nature would solve the issue. This way of thinking, getting inspiration from and create designs based on nature, is called Biomimicry.

Nature can influence your product development in many ways, from the development of new materials to the design of your parts. How does grass come back to its shape after we step on it? It’s lightweight and seems fragile, but grass is actually very strong and can survive different weather conditions as well! Nature came up with many lightweight, but robust designs, which we can use to our benefit and construct our parts. One of the industries that benefit from it a lot is aerospace engineering and mechanical engineering. They use advanced lightweight structures to build aircraft or car parts.

Why haven’t you improved your product with lightweight structures yet?

Don’t waste your time and start using 3D printing technologies to improve your production. Additive Manufacturing will be beneficial to you in many ways. Designs based on nature, new material properties perfectly matching your manufacturing restrictions, lightweight structures which can take a lot of stress or hollowed parts with much lower production costs. Make the most of 3D printing right now!

When you decide to empower your business with Additive Manufacturing remember that we’re here for you every step of the way. If you’re unsure about 3D modeling, contact our Sculpteo Studio. We will provide you with all the help you need. And if you already have your 3D model ready, simply upload it to our website. Don’t forget that you can always hollow your parts right when uploading the file!

Make sure you stay up to date with the latest 3D printing news and tips with our newsletter and Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook