A number of parameters need to be considered will choosing a manufacturing technique for your medical device. Do you need custom parts? Is it a prototype or an end product? Is it a large or low-volume part?

Let’s review the different manufacturing possibilities you have to see which one could be the most adapted to your medical project.

CNC Machining is a subtractive manufacturing technology where parts are created by removing material from a block by using a variety of cutting tools.

CNC Machining is best suited to manufacturing large series of medical devices as well as parts with complex geometries. This technology is adapted to higher volumes.

Also, because of machine costs, training, etc. CNC machining offers quite a high start-up cost, and it won’t be possible to create custom or low-volume parts.

Injection molding is also best suited for high volumes. Indeed, this manufacturing method is particularly helpful for mass production and will offer interesting material options with strong and durable plastics.

This is one of the most common manufacturing techniques, as almost everything around us is manufactured using injection molding.

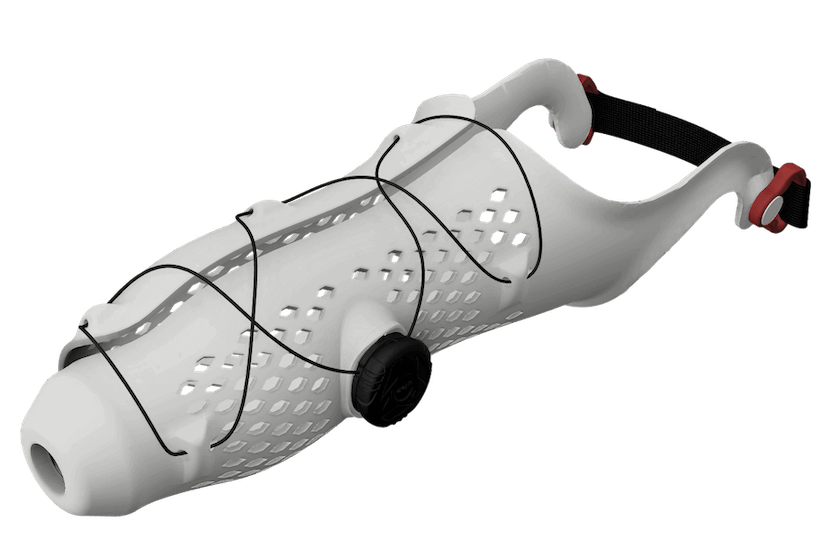

3D printing is a technique that builds objects layer by layer from a 3D file. The process is literally giving you the ability to transform a digital version of an object into a physical version. 3D printing is a manufacturing technique, more and more used today to make proofs of concepts, prototypes, or end-products. Companies are implementing 3D printing at different stages of their manufacturing processes and rethinking their business strategy with this competitive advantage. Medical 3D printing is also becoming quite common.

It is a real asset for medical device manufacturing. It offers interesting material options,

great technologies, and happens to be a real asset for design freedom as well as for mass customization

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook