Home » 3D Learning Hub » 3D Printing for Business » How can 3D Printing can help you grow your business?

How can 3D Printing can help you grow your business?

Introduction

Do you know about all the opportunities that 3D printing could offer you? In this blog post, we are going to show you how you could create your own 3D printing business, innovate, iterate, and make your own fantastic success.

You are looking for tips to understand how you could start a 3D printing business? We will share with you the best ideas for 3D printing business and see what are the best examples of profitable 3D printing businesses. Get inspired by all of these 3D printing ideas!

3D printing, a technology helpful for all sectors

At Sculpteo, we see it every day: 3D printing technology is used by more and more businesses, for various applications. It is now quite helpful for the medical industry, the automotive industry, but also for architecture, aeronautics or even agriculture. The printing possibilities are endless.

Did you check our State of 3D printing? This study helps to understand how additive manufacturing technology is used by different businesses. It confirms that this technology is used by more and more different sectors, from aeronautics to consumer goods.

Do you need some help?

Printing products is possible for anybody and any company. If you need a little help to start your 3D printing business – for example, if you want to learn about digital manufacturing and 3D modeling for additive manufacturing – check out our Sculpteo Studio 3D printing consulting service. Our 3D printing experts are going to give you all the tips, training and information you will need to make the most of 3D printing technology!

Here are the top ways in which 3D printing can strenghten your business

Here is a selection of business examples that make great use of Additive Manufacturing, and some others that are using 3D printing technology to expand and develop their businesses.

We hope that these examples will inspire you. Indeed, you could find the perfect business opportunity thanks to this cutting-edge technology.

Now, let’s see how this relatively new technology enables us to enter a new phase of product development.

1. Rapid prototyping for experimentation and innovation.

One of the main advantages of Additive Manufacturing is its ease of use for rapid prototyping. Indeed, it is a simple and economical way to create and produce prototypes. With this technique, you only have to create your 3D design using 3D modeling software, and modify it as much as you want and need, and print it!

This way, when you want to try different iterations, you only have to change the 3D model and print your 3D file directly. This process could help you to save money and time in the development of your project, and speed up the production process. Indeed, iterating on your project using additive manufacturing is cheaper than with a traditional prototyping technique.

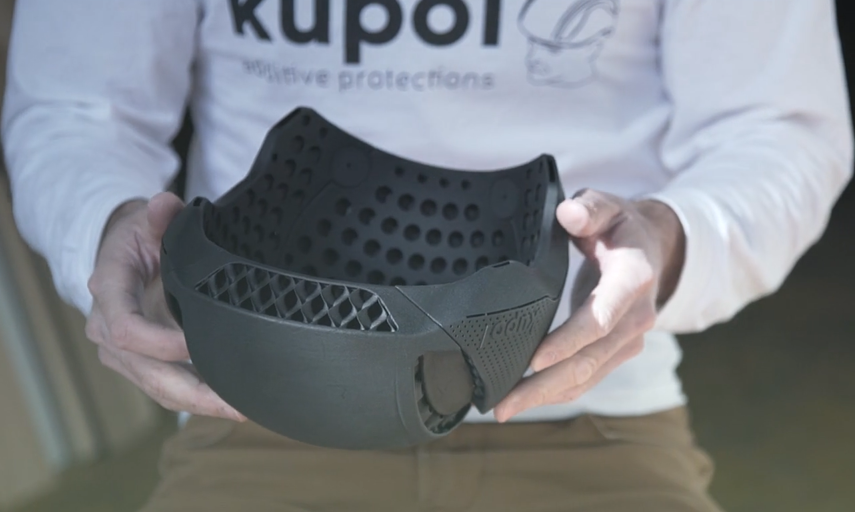

The Kupol Project

Gabriel Boutin, a 3D designer, created the Kupol Project using additive manufacturing technology. It is a bike helmet, 3D printed with the HP Multi Jet Fusion technology, using Sculpteo’s online 3D printing service. This 3D technology helped this innovative designer to develop a relevant and resistant project.

2. The ability to bring mass customization to consumer goods.

Another very interesting aspect of additive manufacturing technologies, is that it enables designers and manufacturers alike to easily and quickly create bespoke products.

Indeed, 3D printing technologies have now proved to be the ultimate manufacturing method for the development of mass-customization into the consumer goods markets.

This is no small feat, considering how strenuous this process would be with conventional manufacturing.

One example of this new paradigm is the eyewear industry.

Example: Netlooks

“We are at the moment in the eyewear industry when we have to do something unexpected. We are at a crossroads of technology and craftsmanship”, explains Pierre Andrieu, founder of Netlooks, a custom-made eyewear company and one of our clients.

The goal of Netlooks is to provide their clients with the ultimate made to measure experience. To achieve that, they complement craftsmanship with the latest technologies. Netlooks uses 3D scanning to get the perfect fit for the client’s head, and Additive Manufacturing provided them with time and cost-efficient prototypes before the final product is hand made.

This 3D technology became an essential part of the production process. Manufacturing the prototypes with Additive Manufacturing allowed the company to work faster, speed up the product development time, and to reduce costs.

3. Tooling costs reduction

Using additive manufacturing to get custom made tools is a very good opportunity for manufacturers to reduce costs, allowing them to adapt their tooling throughout the production process or when changing series. This is a convenient method and also less expensive than other traditional manufacturing techniques.

3D printing can be an asset on different levels, and not only for your products. We saw on our recent blogpost that 3D printing tools could considerably reduce your tooling investment.

Example: Volkswagen Autoeuropa

The car manufacturer has been using 3D printing for 25 years, to manufacture some of its tools but also components used in their car. They have produced over a million parts in the last 25 years. In fact, additive manufacturing has proven so interesting for the group, that they decided to expand their machine park in 2021, adding Binder Jetting to their additive manufacturing capabilities.

No matter what your sector is, 3D Printing can help your company reducie tooling costs, and could be a huge asset for your company.

4. Supply-Chain Management

In the supply chain innovation sector, Additive Manufacturing brings new solutions to existing problems and improves business strategies. That is why companies can take advantage of it to stay on top of their game, and improve their supply-chain resilience.

Recent events like the Covid-19 pandemic or supply-chain disruptions have highlighted the fact that a well managed supply-chain is extremely important for businesses to continue thriving.

With its flexibility and print-on-demand possibilities, this technology proves to be extremely beneficial in today’s competitive world.

Example: Procter & Gamble

P&G found 3D printing to be an asset for Procter & Gamble. Peter Hewett, Global Product Supply Platform Leader, explains: “It only took a short investment of time, understanding the technology and services offered by companies like Sculpteo, to realize how we might be able to solve current business manufacturing challenges in a different and smarter way. We’re already bringing the experts together seeking breakthrough solutions which wouldn’t be possible with traditional technologies”.

5. Achieve the greatest level of detail

Thanks to the nature of 3D printing, with the use of 3D modeling and various extruders, it is possible to achieve very precise results on complex designs, most of which would not be possible with a conventional production method.

Example: Gaëtan Le Penhuel

This aspect of the production was crucial for Gaëtan Le Penhuel, an architect company from Paris, which we had the pleasure to partner with. They needed architectural models delivered in a short time, at the same time, achieving a high level of detail.

Additive Manufacturing was just the perfect solution Gaëtan Le Penhuel was looking for. They wanted to materialize their architectural proposals, and every aspect of the project had to be shown in solid form. Thanks to SLS technology, they were able to achieve precise openings, thin walls, and sharp edges. Industrial 3D printing such as SLS allows for the production of great quality models, quickly and cost-effectively.

6. Create custom-made products easily

Mass customization is one of the essential advantages offered by 3D printing technologies. With additive manufacturing, it is possible to create unique items, opening new horizons in various fields of mass-market produced goods.

For instance, 3D printing can allow for the creation of eyewear adapted to the morphology or style of any person.

From jewelry and ornaments to 3D printed garments and accessories, these amazing benefits can be profitable for many other businesses too.

Example: Octobre71

Octobre71 is a company manufacturing light glasses, and for them, additive manufacturing is an ideal way to produce customizable glasses. For fashion, products often need to be custom made; that is why 3D printing is a great new tool for fashion designers.

7. New Business Models and Small Businesses.

We just saw that 3D printing allows for mass-customization, but it could also be the perfect manufacturing technique to turn your product into a service, whether it is a small business or a larger one.

How? Well, it can lead to amazing business ideas, allowing entrepreneurs to innovate, and create new business models.

If you are about to dive in, don’t forget to check out our guide to avoid six most common mistakes in AM!

With print-on-demand, extreme flexibility, supply-chain resilience, faster time to market, and infinite possibilities for customization, it’s now easier than ever to test out new business models ideas. Rapid prototyping also gives the possibility for aspiring entrepreneurs to test the waters before diving in head first.

Check out our list of the best crowdsourcing platforms, if you have a project you wish to launch in the near future. Of course, you could also boost your KickStarter campaign with 3D Printed goodies!

This manufacturing technique also makes it easier to put the customer at the center of the business model, by creating products that are perfectly tailored to the customer’s needs.

Example: Endeer

Claire Chabaud, one of our former colleagues from Sculpteo decided to start her own business, Endeer from this idea. By combining 3D scanning and 3D printing, they are able to create custom-made armatures for women’s bras, and then insert them in their great underwear collection. The armatures are 3D printed in Nylon PA12 through our 3D printing service. The result is simple: a custom-made bra, perfectly shaped to the women it’s designed for, at a reasonable cost.

Example: Valoptim

Can 3D printing technology be beneficial for property development companies? Certainly! Valoptim is a perfect example of making the most of 3D technologies.

Thanks to Additive Manufacturing, Valoptim took the customer experience, so crucial in any industry, to the next level. They offer their clients a mini 3D printed version of the property they just purchased!

Creating one of a kind model of a flat wouldn’t be cost-effective with any other technology but 3D printing. It is also the fastest way to get the model. Valoptim’s clients can already visualize living in the flat before they even get the keys! It is definitely satisfying for the new owners and brings a lot of innovation and pleasantly surprising, unique experience.

8. Create XL projects

New XL 3D printers are bringing about the creation of impressive things, such as houses, making it possible to 3D print at an architectural scale. This is definitely something to watch in the future, as more and more impressive innovations will continue to flourish around the world.

Example: Apis Cor

Apis Cor, a San Francisco startup 3D printed an entire house in only 24 hours in Russia. This company is making it possible to innovate in the architecture sector using the 3D printing technology. They are using 3D printing technology and an XL 3D printer to create homes in no time and for a lower cost. 3D printing was actually the only solution for this company to create this amazing project, now that concrete 3D printers are available.

Example: MX3D

The MX3D team created a metal 3D printed bridge in the city of Amsterdam. Indeed, 3D printing is an excellent method to develop urban settings such as bridges. This bridge, inaugurated in 2021 is placed right over a canal of Amsterdam, the Oudezijds Achterburgwal!

It is the most massive 3D printed metal structure ever created.

9. Create eco-friendly projects

With less material use, greater flexibilty and the possibilities for the creation of new materials made from recycled plastic, or derived from bio-materials, such as Nylon PA11, it is possible to achieve projects that are friendlier to the environment with AM.

Example: Simusolar

Simusolar is a company created in 2014, developing and implementing small-scale sustainable solutions to bring solar energy to the rural population of Tanzania. Using our online 3D printing service, they developed solar-charged LED lights for fishermen from Lake Victoria, to replace their petrol lights when they fish at night. You can find more details about this project in this blog post.

Example: Adidas

We already saw on our blog that additive manufacturing is an amazing manufacturing method to create custom-made shoes. Adidas created different 3D printing projects and has been working on sneakers made with plastic found in the ocean. It is actually showing how plastic can be recycled and used by 3D printing businesses. Recycling plastic parts could be more and more important in the 3D printing industry in the upcoming years.

10. Create spare parts

With the ability to easily produce different iterations of a same part, and great flexibility and versatility, it is only logical that the automotive industry would benefit from such possibilities. As we’ve seen in this article, the industry has already embraced the technology for mass production of their current models, but older models may benefit from the technology as well. For instance, it is now easier than ever to recreate spare parts for vintage vehicles, or limited series cars.

Of course, the automotive industry is not the only one in need of spare parts, and it’s easy to see how manufacturers of any field might take advantage of on-demand spare parts prodution.

Example: Jaguar

Jaguar, the famous car manufacturer, is using 3D printing to create spare parts for its old vehicles. The company used 3D scanning to recreate the classic XKSS model from 1957. Additive manufacturing is the best way to recreate parts that are no longer manufactured and not available on the market. It is offering new business possibilities, even for big brands such as Jaguar! You have to create 3D files of the unique parts that you need and print them!

Improve your manufacturing products using 3D printing

Improving your products thanks to a better 3D design

Additive manufacturing can help you to improve your existing products, by making them lighter or even to develop a design that might be too difficult to create with a traditional manufacturing method. For example, you could add lattices to your product, or strengthen your 3D print using jigsaw structures.

It is also really convenient to create objects in just one part. You may know it, but some intricate designs can be challenging to develop in only one part. But additive manufacturing technology allows you to do that.

Improving your products thanks to 3D printing materials

As you can see on our 3D printing material pages, there are a lot of different materials available. Each material has its properties; some of them are better for rapid prototyping; others are better for production. Some are flexible and others more resistant to stress.

For example, you can use Stainless Steel 316L with DMLS technology for mechanical parts, but you could also consider Stainless Steel 316 produced with Binder Jetting. Find the right metal material for your project with our ultimate guide.

You have to find the right material for your project. But once you find it, it can give you the possibility to improve the final properties of the product that you want to manufacture. Indeed, the same product manufactured with a different material can have a lot of different properties: it can be lighter, it can have a higher resistance to heat, etc. The possibilities are endless, just by choosing the right one. You can find a cheaper material with better properties only by using 3D printing technology. Think about it!

Start your own company thanks to Additive Manufacturing!

We hope that you are getting inspired by all of these profitable 3D printing business perspectives.

Are you ready to scale your own business thanks to 3D printing? Keep in mind that everything is 3D printable, and this technology could help you start a new adventure and grow your business.

Starting your own 3D printing business doesn’t have to be that hard. You need business plans, and with the help of an online 3D printing service, you ‘re good to go! Contact us if you need some help or simply upload your 3D files and start your manufacturing process and today.

If you want to read more about 3D printing applications and 3D printing business ideas, we recommend you to subscribe to our newsletter and follow us on Linkedin!

What are the benefits of using 3D printing technology for my business?

3D printing offers numerous advantages for businesses, including rapid prototyping, mass customization, cost reduction in tooling, supply chain management improvements, detailed and intricate design capabilities, eco-friendly projects, creation of spare parts, and more. These benefits can streamline production processes, enhance product development, and open up new business opportunities.

How can 3D printing improve existing products through better design and materials?

Additive Manufacturing allows for the optimization of product design and material selection, leading to lighter, stronger, and more functional products. By leveraging advanced materials and design techniques, businesses can enhance the performance and properties of their products, providing a competitive edge in the market.

How can 3D printing be utilized for rapid prototyping and innovation?

Additive Manufacturing simplifies rapid prototyping by allowing designers to quickly iterate designs and produce prototypes economically. With 3D modeling software, designs can be modified and printed with ease, facilitating experimentation and innovation. For instance, the Kupol Project showcases how a bike helmet was 3D printed using HP Multi Jet Fusion technology, enabling the designer to create a relevant and durable product.

Can 3D printing enable mass customization in consumer goods?

Yes, 3D printing technologies empower businesses to create bespoke products efficiently. For example, companies like Netlooks in the eyewear industry utilize 3D scanning and Additive Manufacturing to offer customized products tailored to individual customers’ needs. This flexibility in manufacturing allows for unique consumer experiences and product personalization at scale.

How does 3D printing reduce tooling costs for manufacturers?

Additive Manufacturing offers custom-made tooling solutions that are cost-effective and adaptable throughout the production process. For instance, Volkswagen Autoeuropa has been utilizing 3D printing for over 25 years to manufacture tools and components for their vehicles, resulting in significant cost savings and production efficiencies.

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook