Capabilities

With 75+ combinations of 3D printing materials and finishings, we guarantee the highest professional quality from each of our state-of-the-art 3D printers and printing techniques.

- ISO 9001

- Fast Turnaround

- Secure File Upload

Login

If you have any trouble logging in to your account, contact us.

Sign Up

To start 3D printing or Laser Cutting, you'll need to create an account here. Once done, you'll be able to upload your files and get live quotes of yours parts

Already have an account? Log In

* With this technology, we offer a 24H Express option. Orders passed before 15:30 (GMT + 1) will be ready for pick up or shipping by 11:00 am (GMT + 1) the following day.

Recycled PET filament

Discover Sculpteo’s extensive range of 3D printing materials, tailored to different printing technologies. From Selective Laser Sintering (SLS) to HP Jet Fusion and beyond, Sculpteo ensures optimal material performance for every project.

Indeed, there are many different 3D printing materials on the market, and the right material is essential for the perfect outcome of your 3D-printed project. Every material has different properties and possibilities so, let’s have a closer look at our range of materials and printing technologies, exploring their unique properties and real-world applications.

Polymers, most commonly known as plastics, are still today’s largest material offering in the additive manufacturing industry.

Let’s have a look at what’s available at Sculpteo.

Employing a high-powered laser to sinter powdered materials layer by layer, this technology offers great precision.

This enables the production of robust and functional parts from a variety of materials.

Sculpteo’s SLS materials include:

Flexible and strong, it is a durable material, ideal for producing functional prototypes and end-use parts requiring durability and strength. Chemical smoothing is often used as a finishing option, on this material.

Applications examples: custom gears, automotive components, electronic casings, consumer goods.

Exhibits excellent elasticity and resilience, perfect for producing flexible parts.

Applications examples: shoe soles, custom seals.

Reinforced with carbon fiber for enhanced stiffness, this material is highly robust and will be suitable for high-performance applications.

Applications examples: drone frames, sports equipment.

Boasts superior mechanical properties and chemical resistance.

Applications examples: medical devices, industrial tooling, machinery components.

Engineered with electrostatic discharge properties, crucial for applications requiring static control.

Applications examples: electronic enclosures, assembly fixtures.

Infused with glass fibers for improved stiffness, ideal for industrial applications.

Applications examples: machine housings, tooling fixtures.

Flame-retardant material ensuring enhanced safety and compliance.

Applications examples: aerospace interiors, electrical enclosures.

HP’s proprietary technology, Jet Fusion technology utilizes fusing agents and heat for precise 3D printing.

Sculpteo’s HP Jet Fusion materials include:

Known for its mechanical properties and surface finish, perfect for functional prototypes.

Applications examples: automotive parts prototypes, engineering parts.

This bio-derived polymer exhibits high strength and impact resistance, making it suitable for demanding applications that require durability and reliability.

Applications examples: Industrial tooling and machinery parts, medical orthesis and prosthetics

This material offers excellent chemical resistance and durability, making it ideal for functional prototypes and end-use parts requiring resilience and flexibility.

Applications examples: customer containers and packaging, industrial equipment components

Offers outstanding flexibility and impact resistance, ideal for soft-touch components.

Applications examples: ergonomic grips, wearable accessories.

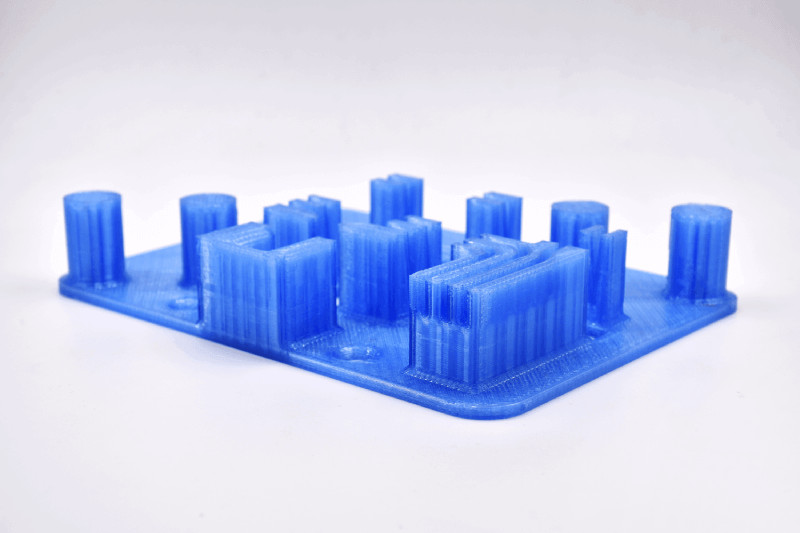

Ultrafuse® rPET is a material made from recycled PET plastic, offering environmental benefits while maintaining durability and versatility. It offers the same characteristics as Virgin PET, such as food safety. It will be ideal to create prototype and end-use parts, with its original blue translucent hue.

Applications examples: educational models and prototypes, packaging solutions, household items

Stereolithography (SLA) technology cures liquid resin into solid objects using UV light.

Sculpteo offers Prototyping Resin suitable for SLA, providing detailed and high-resolution prints.

Applications examples: intricate jewelry designs, sleek prototypes for creative projects.

DLP and LCD technologies cure resin into solid objects using light.

Sculpteo offers Ultracur3D® resins for DLP/LCD, tailored for specific applications:

Highly accurate resin, will be perfect to print large parts for demanding applications.

Application examples: Engineering, functional, large-scale parts, series.

Transparent and bio-compatible, this impact-resistant resin can achieve great levels of detail.

Applications examples: Transparent housing cases, medical tooling, prototypes.

Loaded with ceramic particles, this distinctive looking resin is a high performance material providing exceptional rigidity, electric insulation, resistance to heat, and reliability.

Applications examples: parts for electric insulation, cosmetic vials and bottles.

This unique and cutting-edge resin is specifically tailored to dental applications, with its high accuracy and large production capabilities.

Applications examples: accurate dental models and thermoformed aligners molds.

Polyjet technology jets layers of liquid photopolymer onto a build tray and cures them instantly with UV light.

Very smooth and precise materials, highly accurate, with an aspect comparable ton injection molded plastics, these materials will offer you a great range of varying textures and colors thanks to their array of finishing options.

Applications examples: realistic prototypes with varying textures and colors, ornemental objects, functional parts if the mechanical constraints are not too important.

Rigid Polyurethane

Elastomeric Polyurethane

Whether you want to print Stainless Steel, Aluminum, Titanium, Bronze or Silver, Sculpteo offers a wide range of metal additive manufacturing technologies, including:

Do not hesitate to visit each particular material page in order to understand which technology best suits your needs, or contact our sales team if you need assistance.

Not only do we 3D print, but we also offer Laser Cutting and Engraving! Just make sure your vectorized file is ready, and visit our Laser Cutting Page to select your material.

Sculpteo’s dedication to providing a diverse range of 3D printing materials ensures optimal performance and quality for every project. Whether you’re creating industrial prototypes, consumer products, or intricate jewelry designs, Sculpteo’s materials selection will allow you to unleash the full potential of 3D printing.

Need help with the choice of your 3D printing material? Contact our experts to get the best counseling!

Explore Sculpteo’s material offerings today and transform your ideas into reality!

Sculpteo provides a selection of high-performance materials with exceptional mechanical properties, including superior tensile strength and Young’s modulus, ideal for engineering and industrial applications requiring reliability and durability.

Yes, Sculpteo provides finishing options such as chemical smoothing or polishing to enhance the surface finish of your 3D printed parts. Do not hesitate to check out our Finishing Options Page to discover all the finishes available.

Yes, Sculpteo provides metal additive manufacturing services with materials like titanium and stainless steel, silver, brass and aluminum. Explore our range of metal materials to see which one is the best for your needs!

We offer a variety of plastic materials, including polymers and photopolymers. Whether you want to create prototypes, beautiful end-products, consumer goods or functional parts with high requirements for your engineering needs, we have the right material for you.

Discover the post-processing options for 3d printed parts.

With +10 years of expertise in additive manufacturing for production and prototyping, Sculpteo brings +75 materials and finishes to develop your most ambitious projects. Our online 3D printing service provides professional 3D printing with rigorous quality control.

Create a free account and upload your 3D files, select your material, technology, and post-processing options, and order online.

We’ll take care of the rest in our industrial ISO 9001 factory.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook