Christmas is coming soon, it is thus necessary time to make your own candle holder, for the decoration of your Christmas tree, for example.

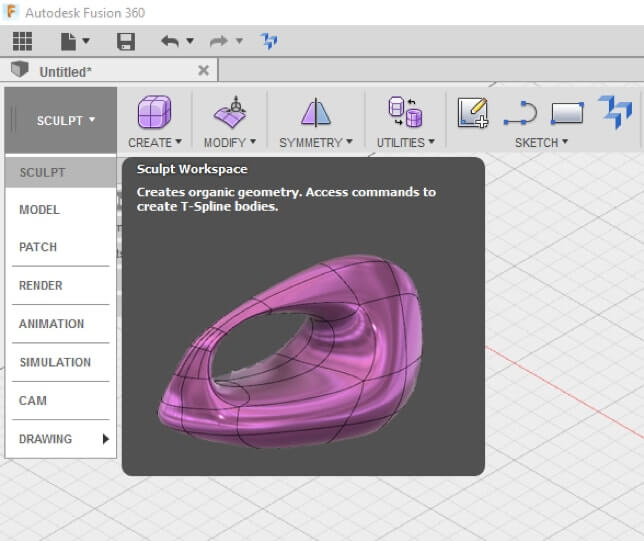

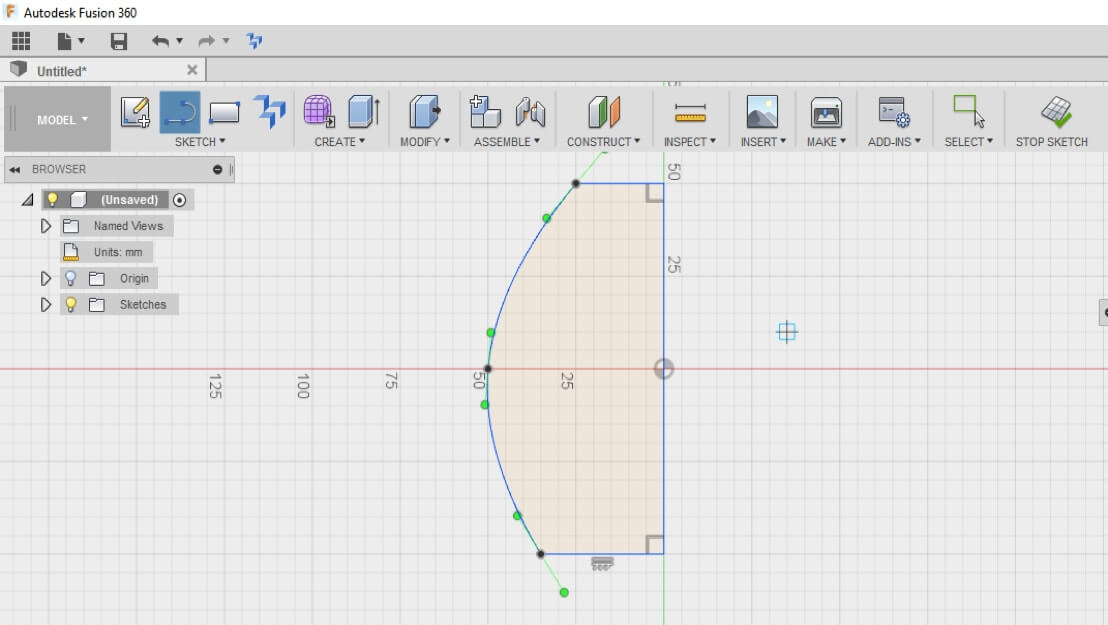

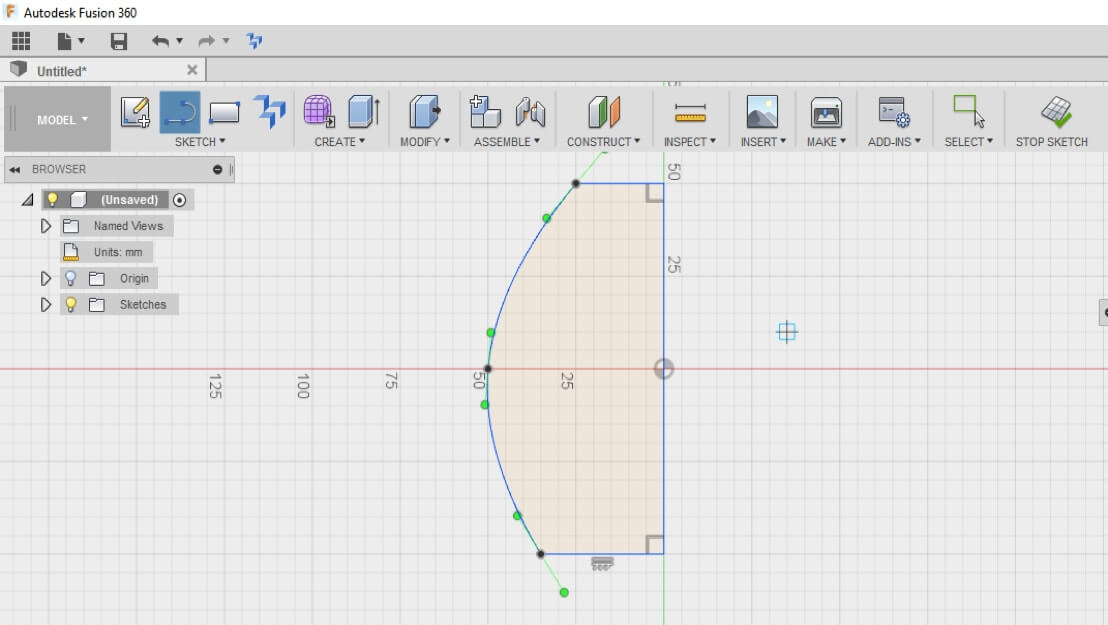

Begin your sketch by using the tool splines in the sketch menu. Then close your surface.

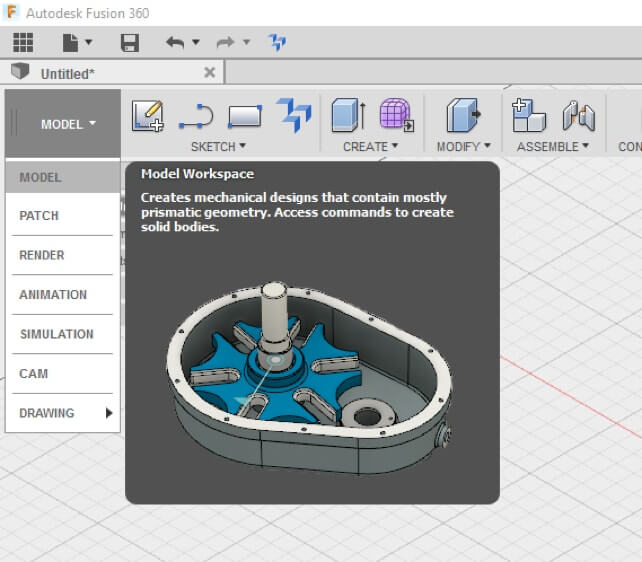

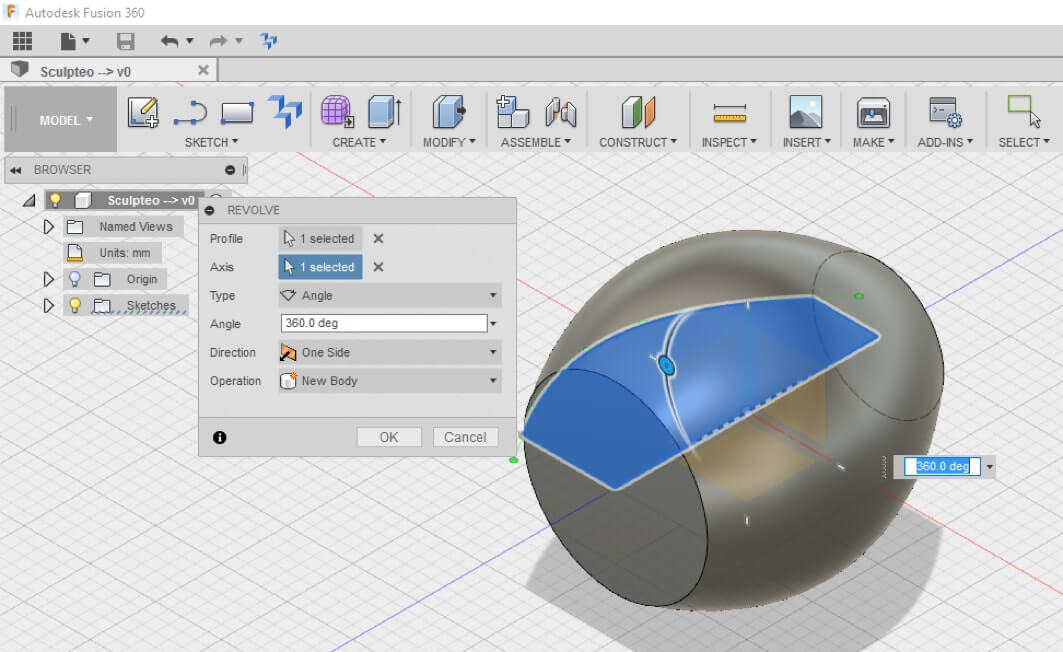

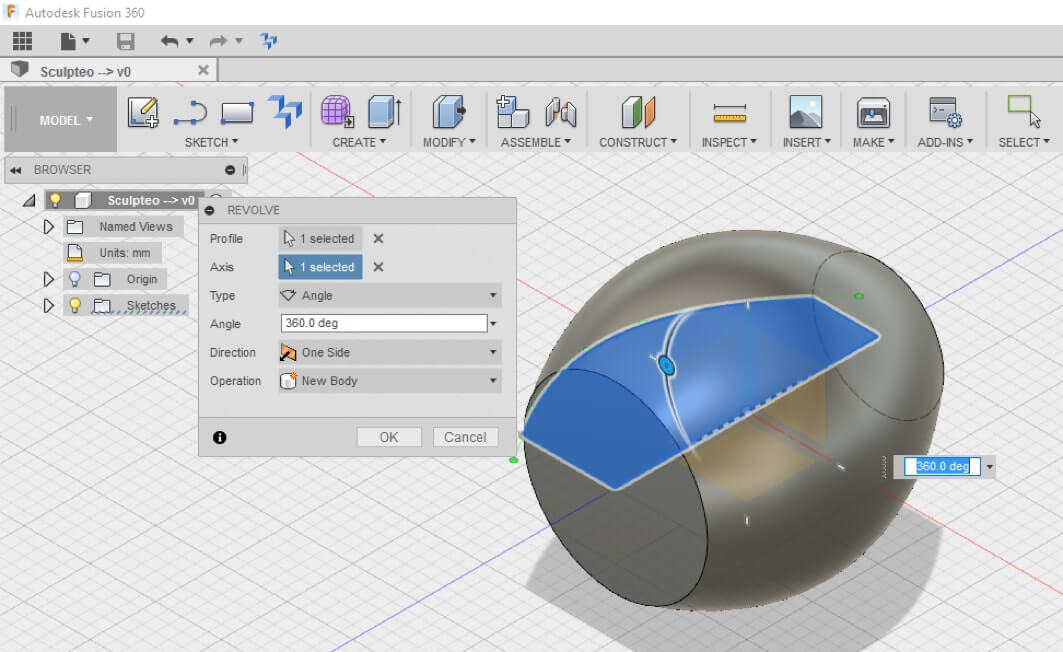

Create then a volume with an operation of Revolution, in the workshop Create.

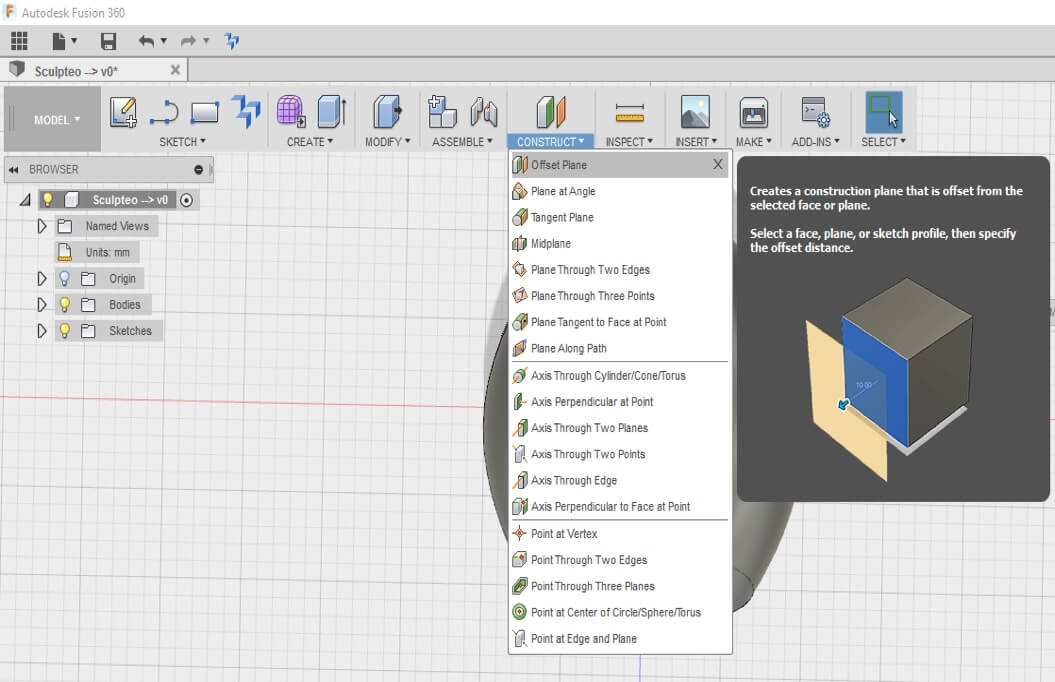

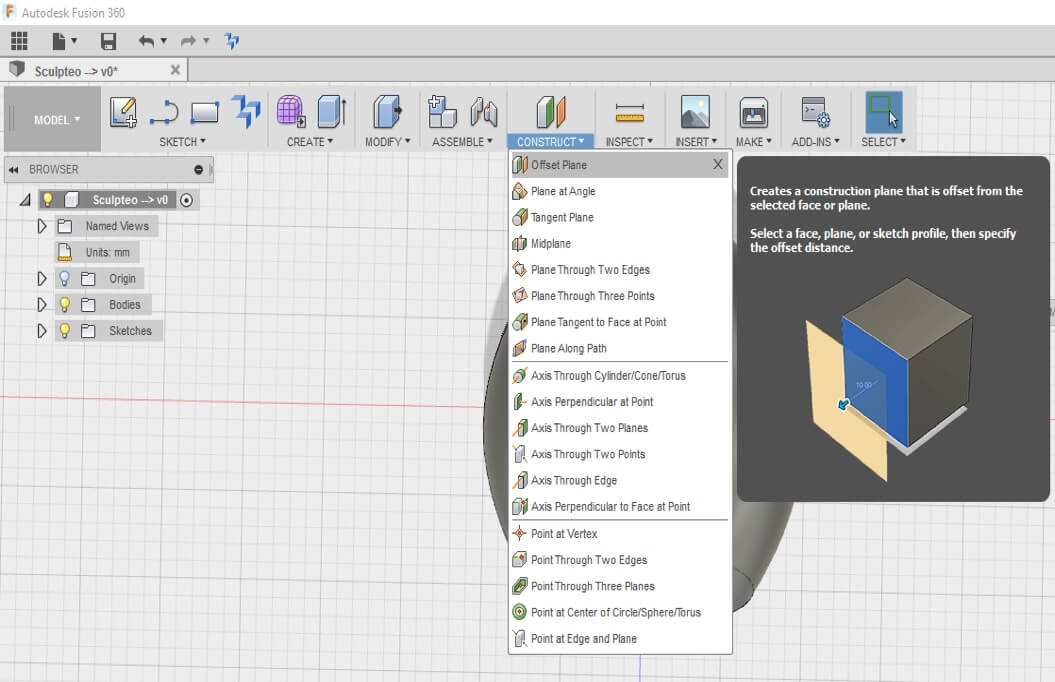

To create the base on which will be positioned the candle, it is necessary to separate the body in two bodies, using the function Offset Plane.

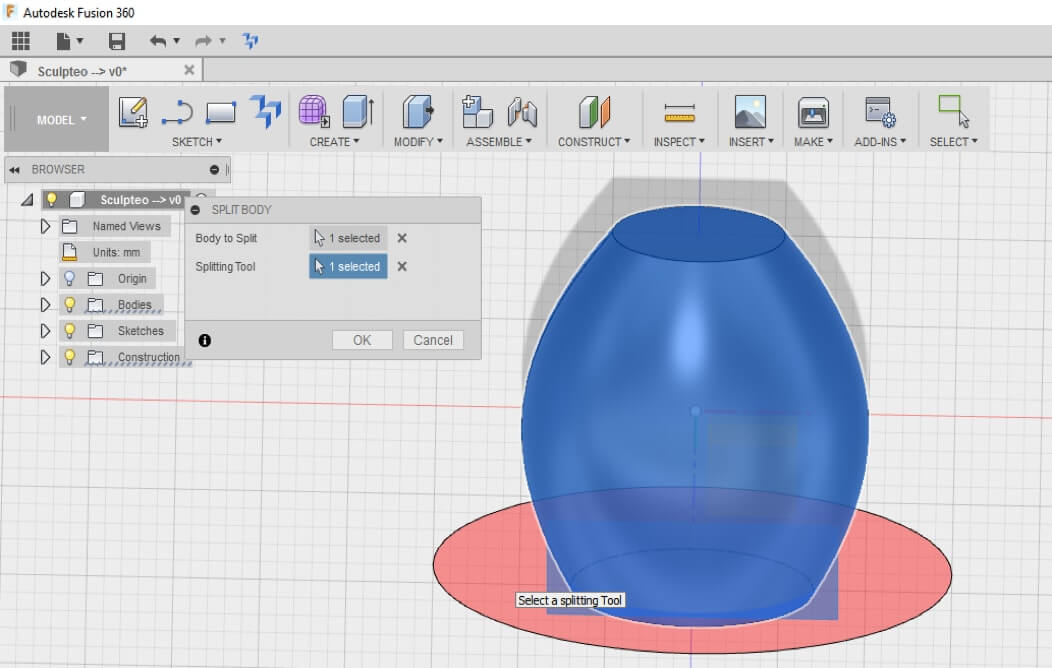

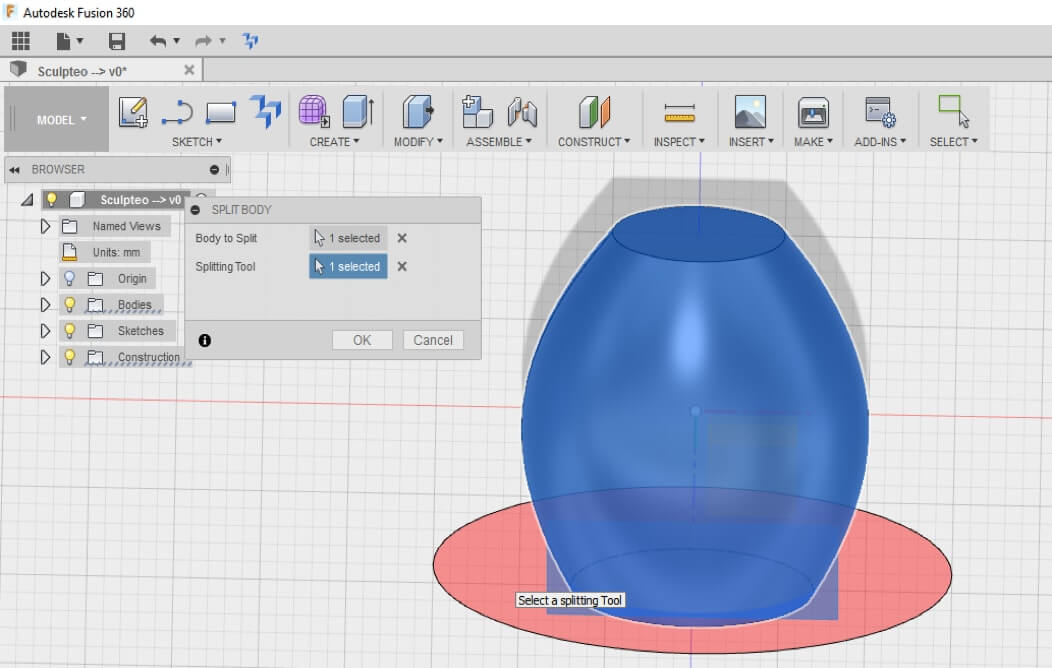

Then, in the Modify Menu, select the Split Body tool.

You can now see two different bodies. But be careful, if you wish to print separately the two bodies, it is necessary to transform them into two separated components.

NB: Even if 2 bodies are different, they will be printed as a single component. As evoked previously, if you wish to print in various materials these two bodies, it is necessary to transform the bodies into two separated components.

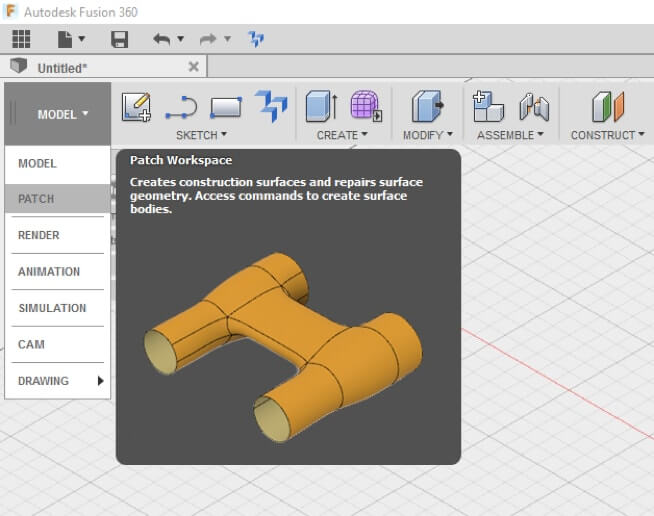

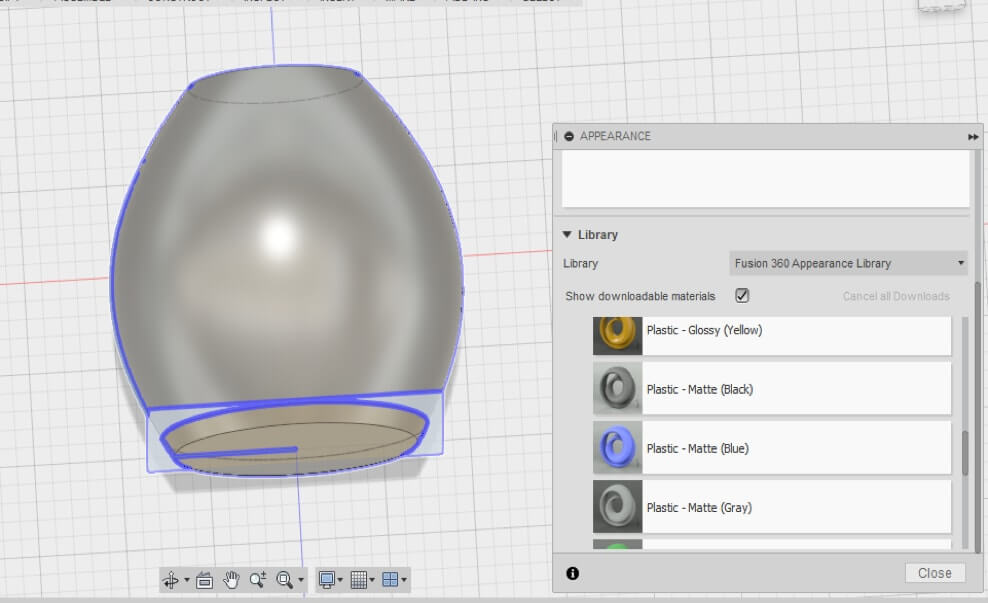

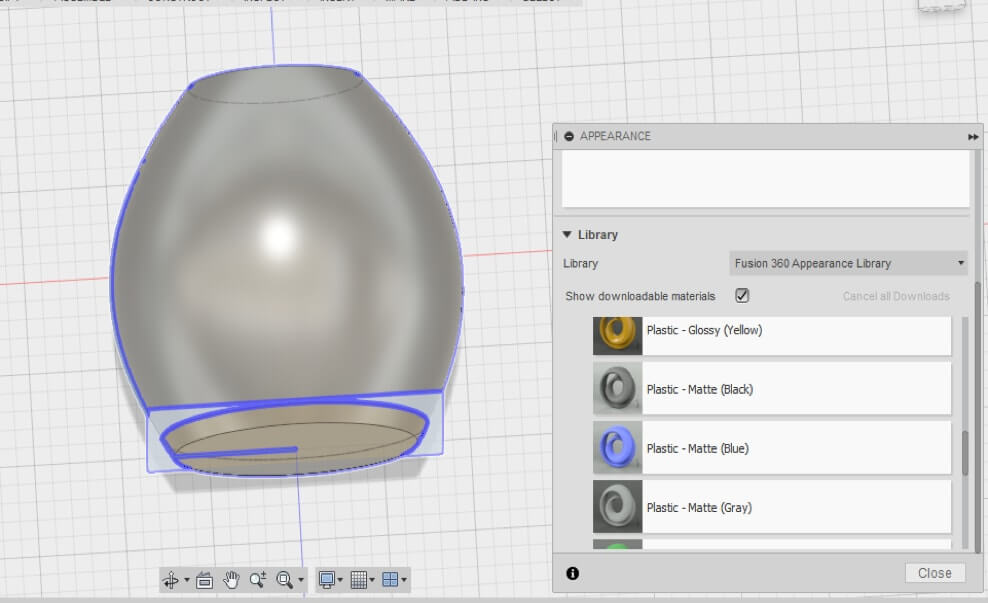

To modify the appearance, right click on the body (Appearance), then select the desired material. This is only for the visual appearance: the choice of the material to take into account the mechanical resistance is made in the Simulation workshop.

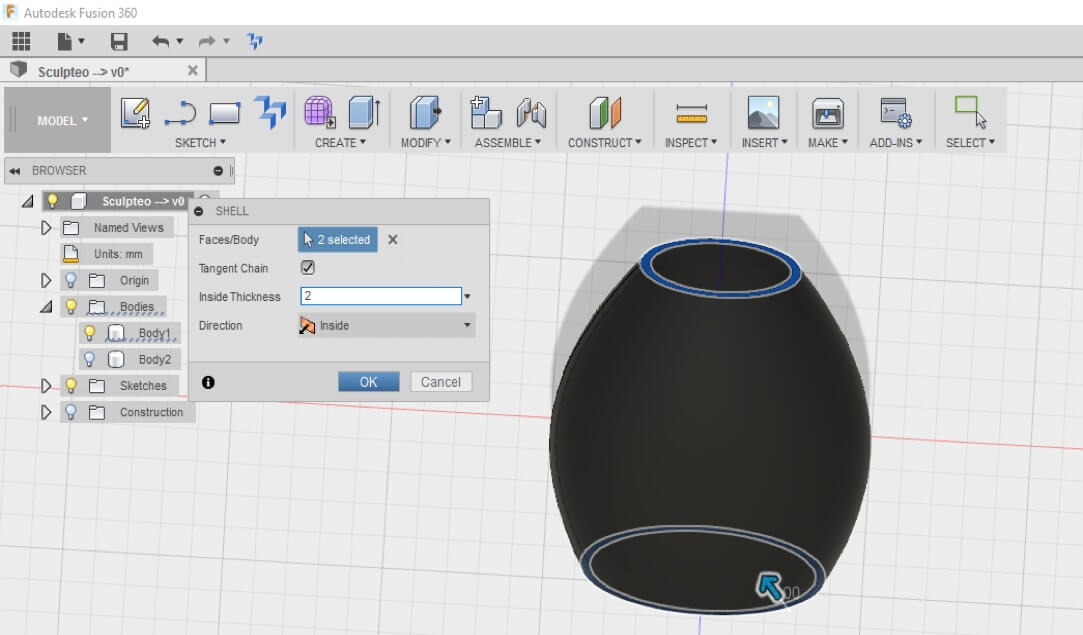

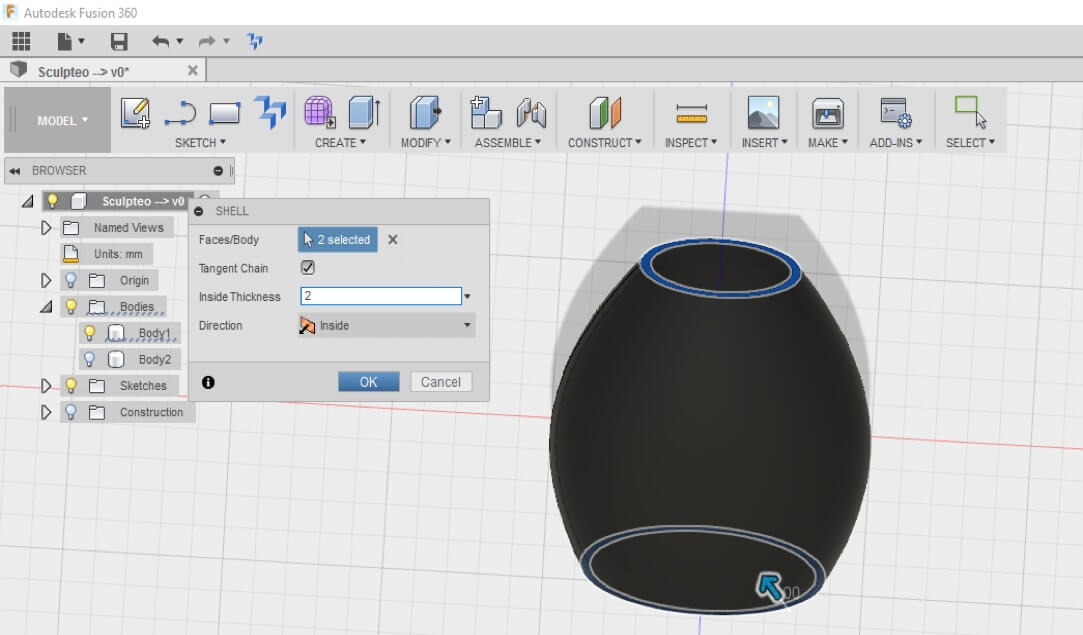

Uncheck the second created body (the base), by marking in the arborescence of modeling the yellow light which becomes then white. Then use the function Shell to give a thickness to the body #1.

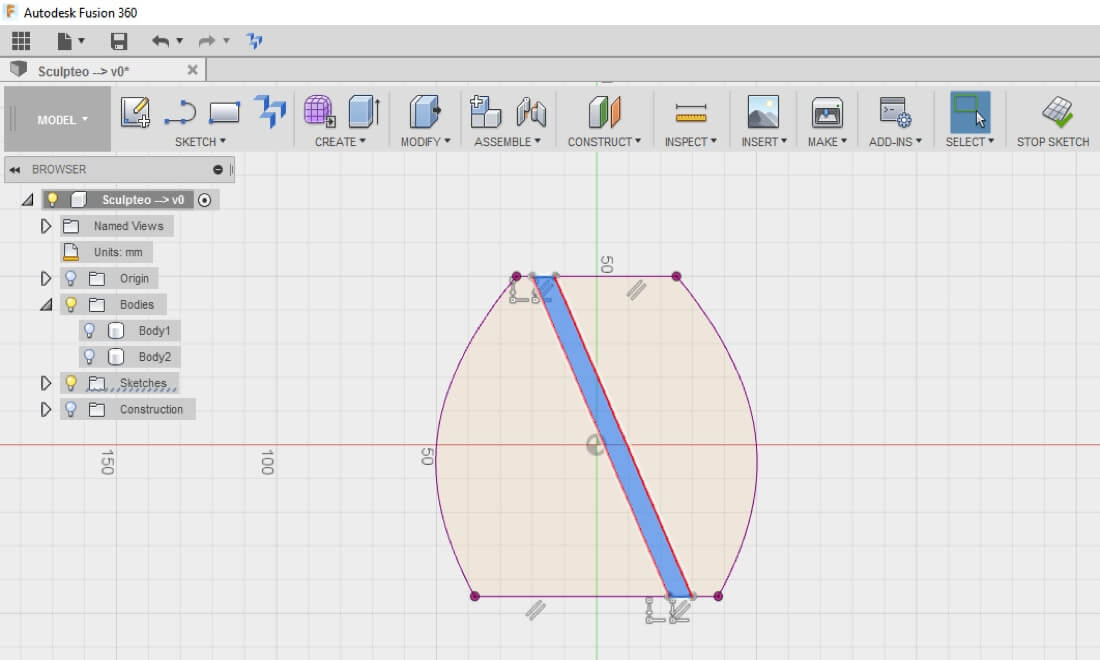

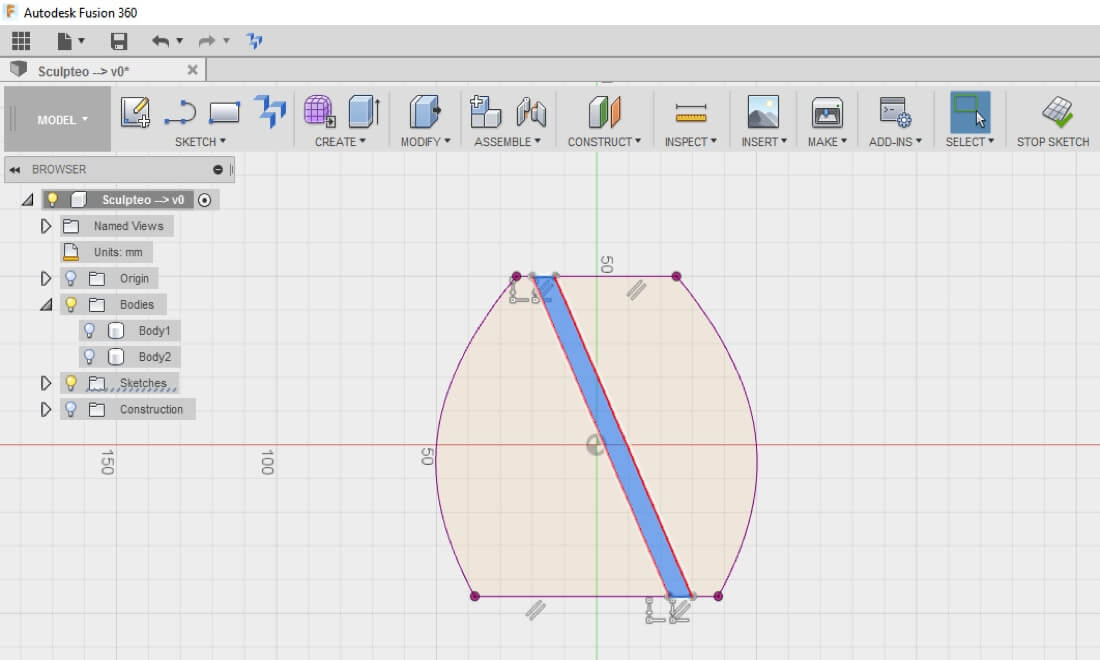

Recreate a new sketch, and throw the view on the same plan as the very first created sketch (SKETCH → PROJECT).

Draw then a rather fine strip, then extrude this strip according to the normal for the plan, and symmetrically with regard to the plan.

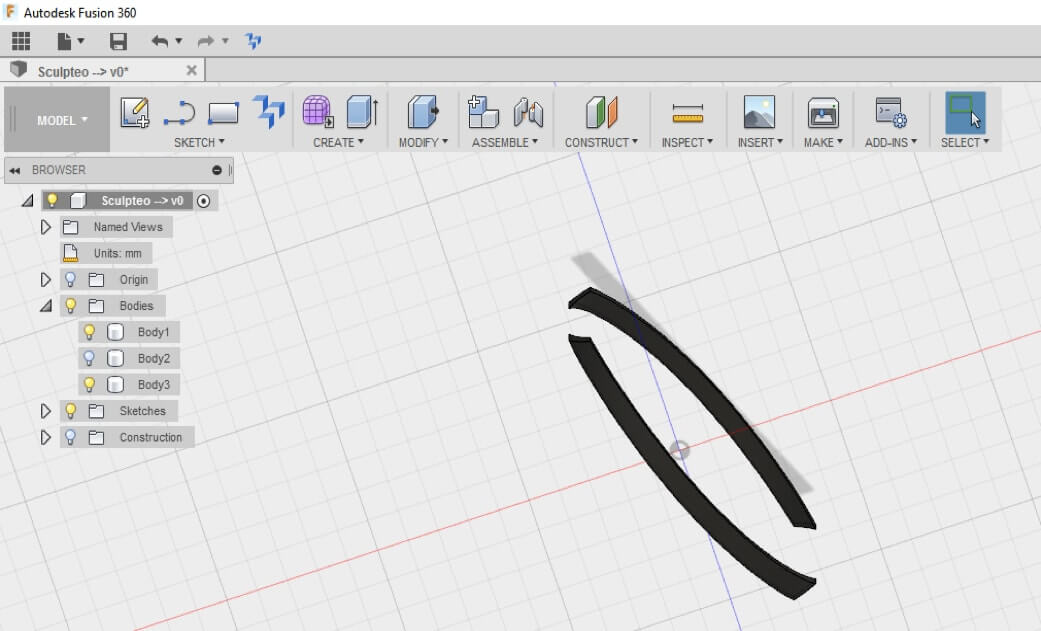

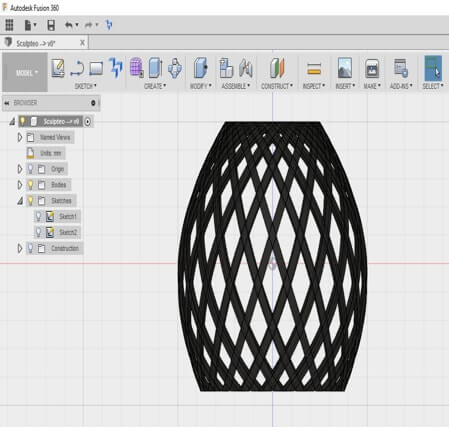

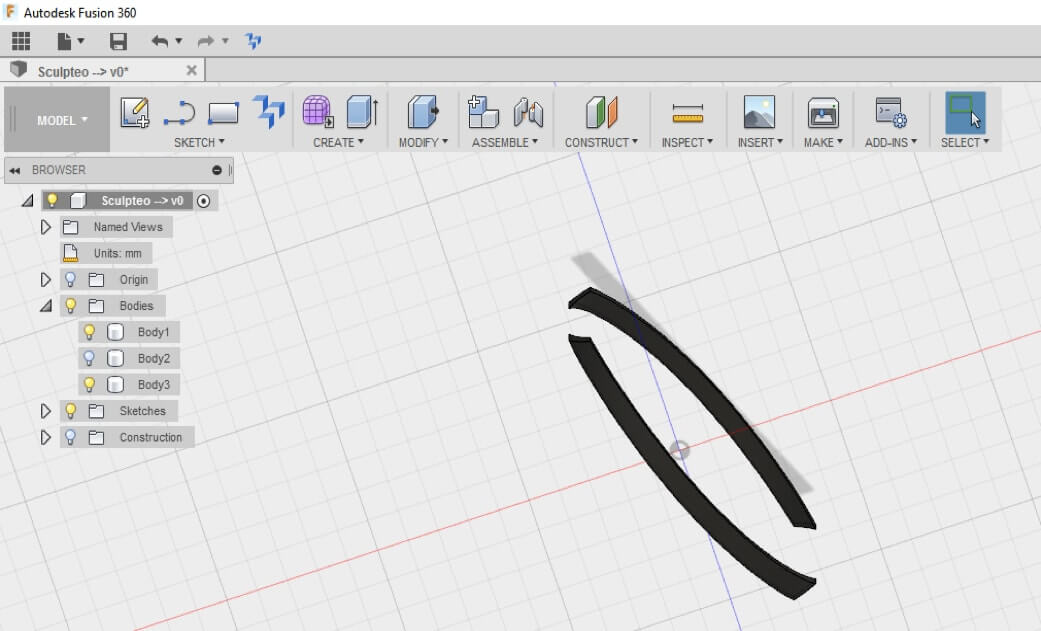

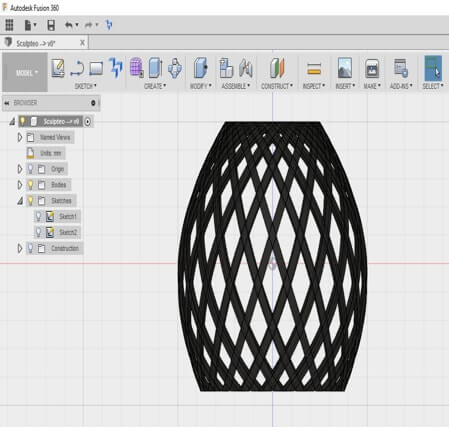

Create then the intersection between the 1st created body and the new created volume. You obtain then this body.

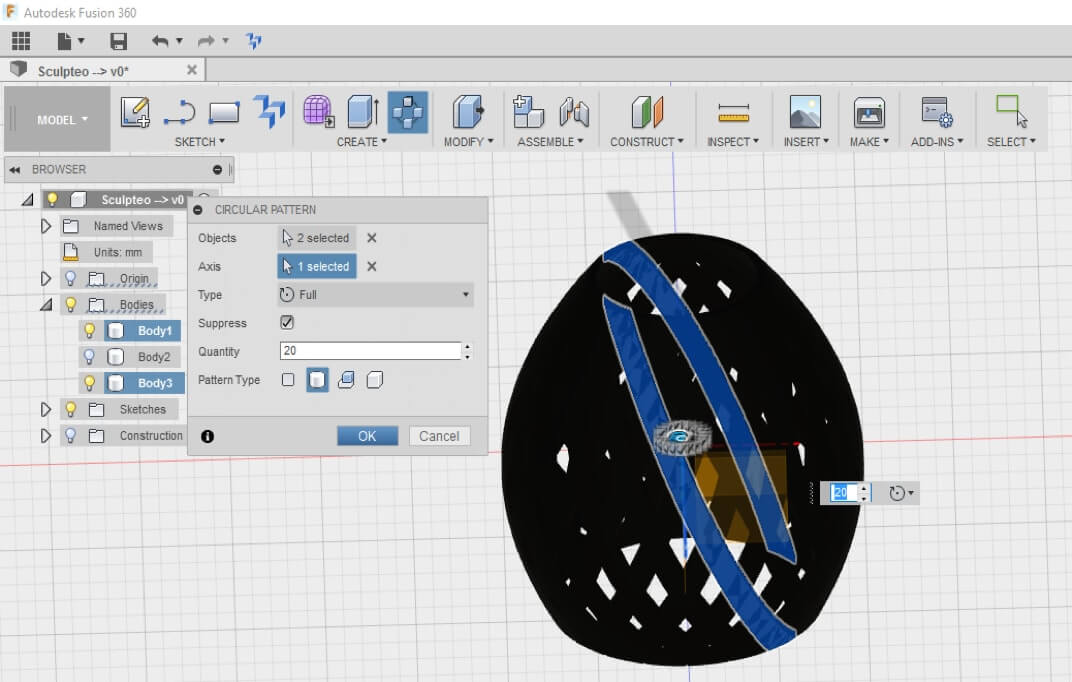

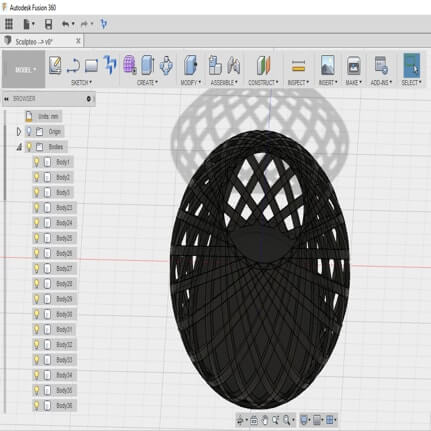

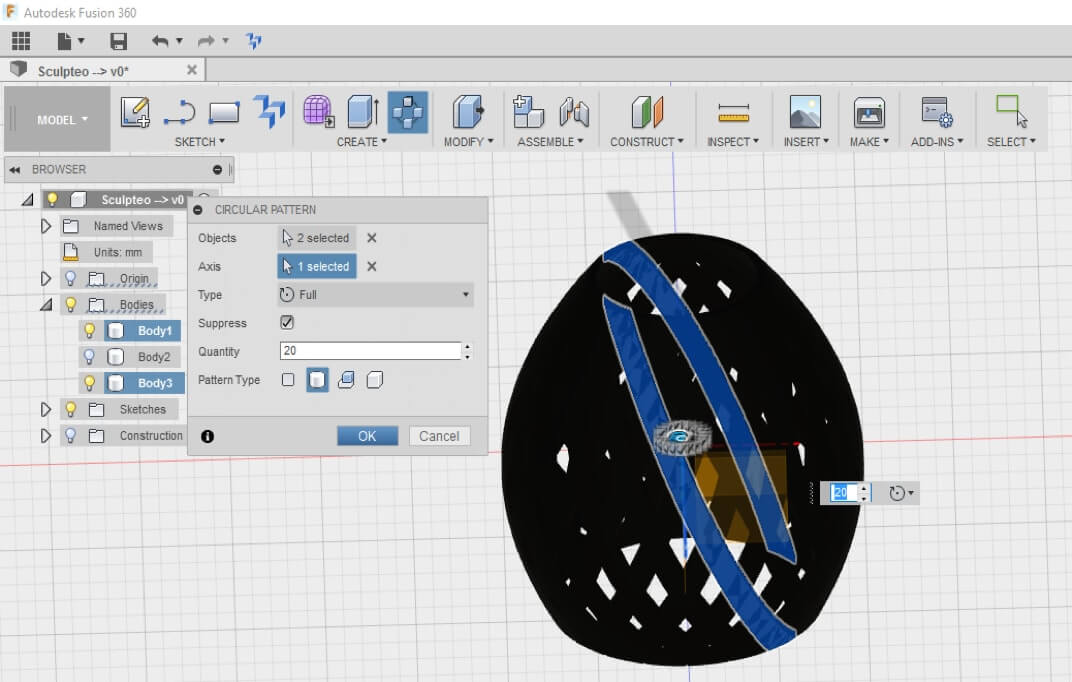

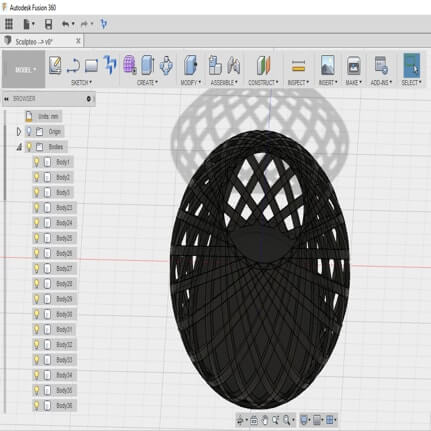

Reproduce this shape, with the Circular Pattern tool. You can determine the number of desired bodies, which will impact directly on the luminosity emanating from your candle holder.

Your candle holder is now ready for 3D printing. You can from now upload it on Sculpteo.

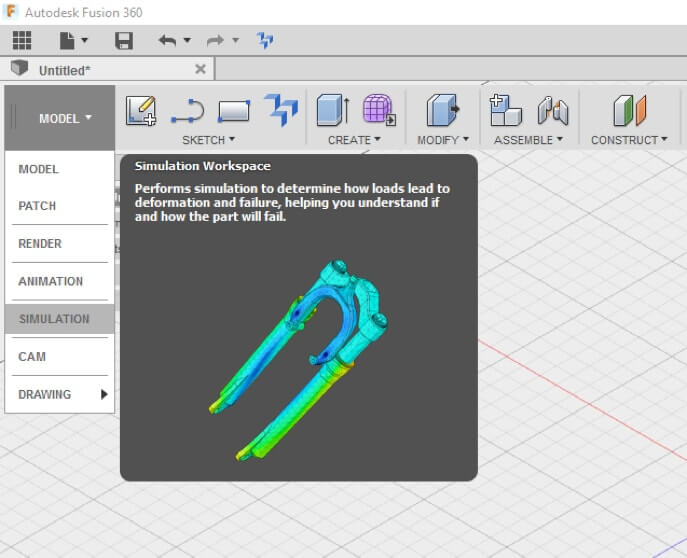

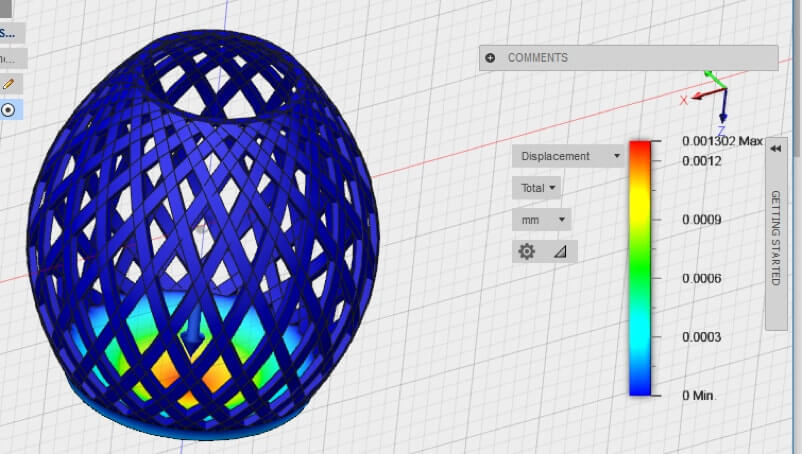

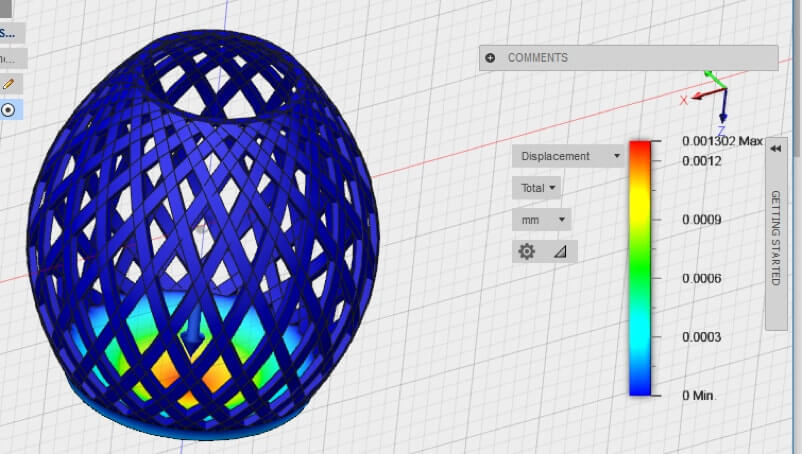

Simulation Workshop

In our case, a simulation of the mechanical resistance of the part and the weak spots is not a very useful study because of the very light weight of a candle.

Nevertheless, it can be interesting just to test the Simulation workshop.

Go to the module Simulation and select the desired material.

We selected here some Polyamide (PA12) material, often used in SLS 3D printing. We apply a load of 5N (that is the strength of the weight of a candle of 500g, if we applicate the physical formula W = m * g, g being the gravitational acceleration and whose the value is around 10). After solving, we can immediately locate the most fragile zones (in red).

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook